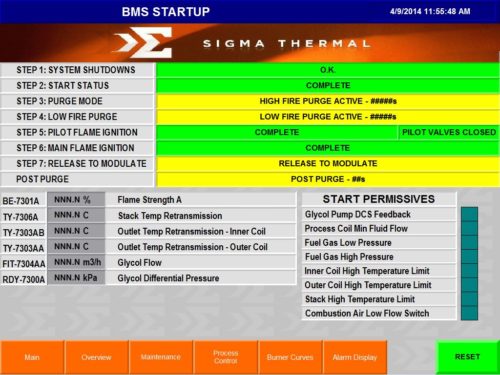

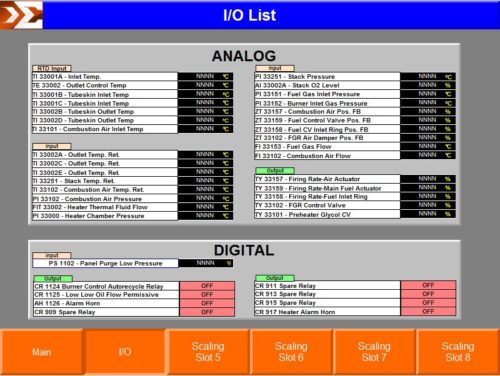

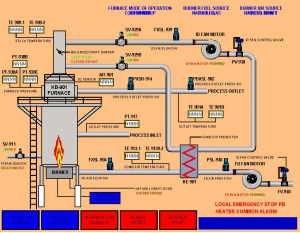

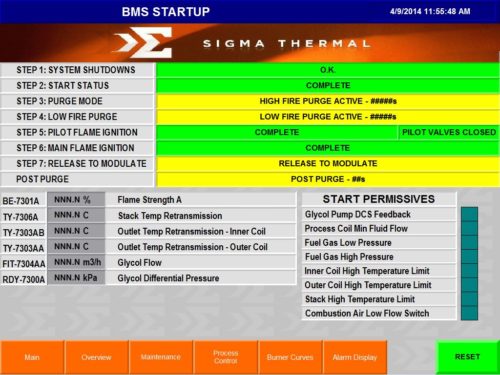

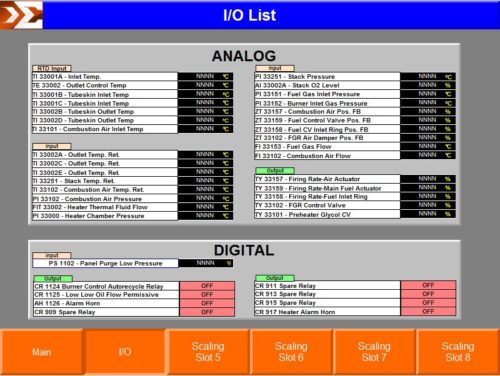

Sigma Thermal offers several Burner Management Systems (BMS) and Combustion Control Systems (CCS) to meet a wide range of customer requirements and environmental conditions. These solutions range from low-cost microprocessor based systems to complex Safety Instrumented Systems (SIS) using a Programmable Logic Controller (PLC).

BMS and CCS systems are provided for maximum safety and reliability while maintaining a simple and cost effective design. Our systems provide safe and efficient operation of fuel fired process heaters without the need for constant operator attention.

Products and Services

Products and Services

Microprocessor Based BMS Systems

Panel Mounted Temperature Controllers

PLC Based Safety Instrumented Systems (SIS)

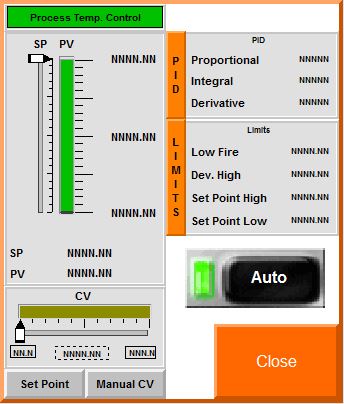

Advanced Combustion Control Systems

Efficiency Upgrades & Modifications to Aging Systems

Local/Regional Code Compliant Audits & Studies

Benefits and Options

Single and Multi-Burner Applications

Fail-Safe Technology

Increased Safety and Reliability

Simplex and Redundant Configurations

Enhanced Operator Interface Modules

High Availability & Fault Tolerant Design

Advanced Diagnostics & Communications

Independent Fuel Air Ratio Control (F.A.R.C.)

Temperature Compensation