Dryers & Kilns

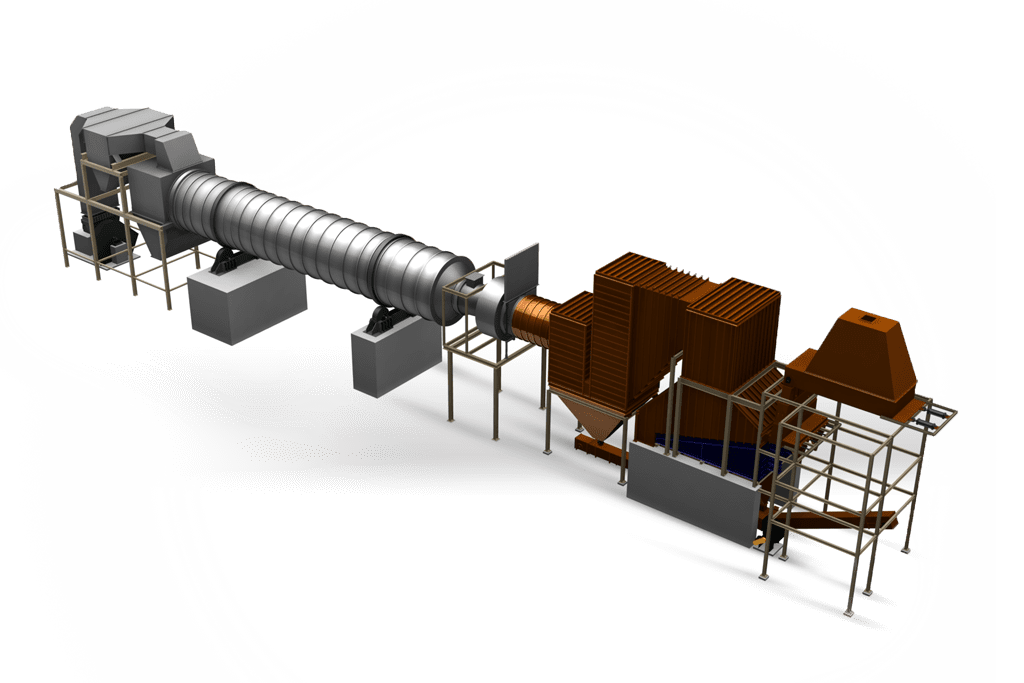

From biomass combustion to the preparation of materials for lumber and engineered wood production, drying biomass is often a central process in wood products manufacturing.

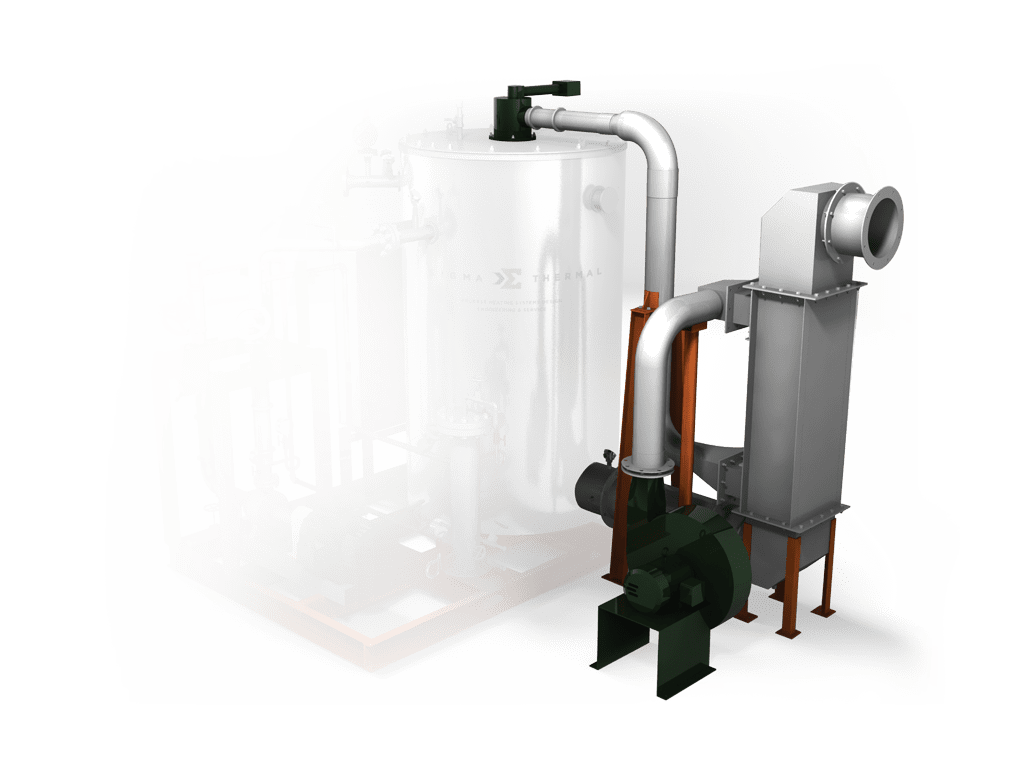

Biomass dryers come in a variety of configurations, and heat energy systems often need to consider many plant-specific variables to obtain maximum energy and throughput. Lumber kilns also use a variety of heat energy sources, and every individual facility and wood species will have their own specific needs. Natural gas or fuel oil serve as a primary energy source, but it is also very common to burn wood waste from the plant to either supplement or entirely replace the need for fossil fuels.

Biomass Fired Systems are complex, and it is imperative that fuel handling, combustion control, ash removal, and waste heat recovery systems be designed to give operators maximum combustion quality with clean emissions. Sigma Thermal engineers are heat energy management experts. We optimize our heating systems to provide the most cost-effective operation possible and provide energy audits to ensure that recovery potential is fully realized. Whether considering a traditional fossil fuel-fired system, or a biomass-fired system, Sigma Thermal has the applied engineering expertise to ensure your facility’s potential is fully realized.