Amine & Glycol Reboilers

In natural gas and crude oil refining, corrosive hydrogen sulfide (H2S) and carbon dioxide (CO2) gasses must be removed from the hydrocarbon stream before the respective fuels can be stored or introduced into the pipeline. To do this, amine and glycol reboilers are used.

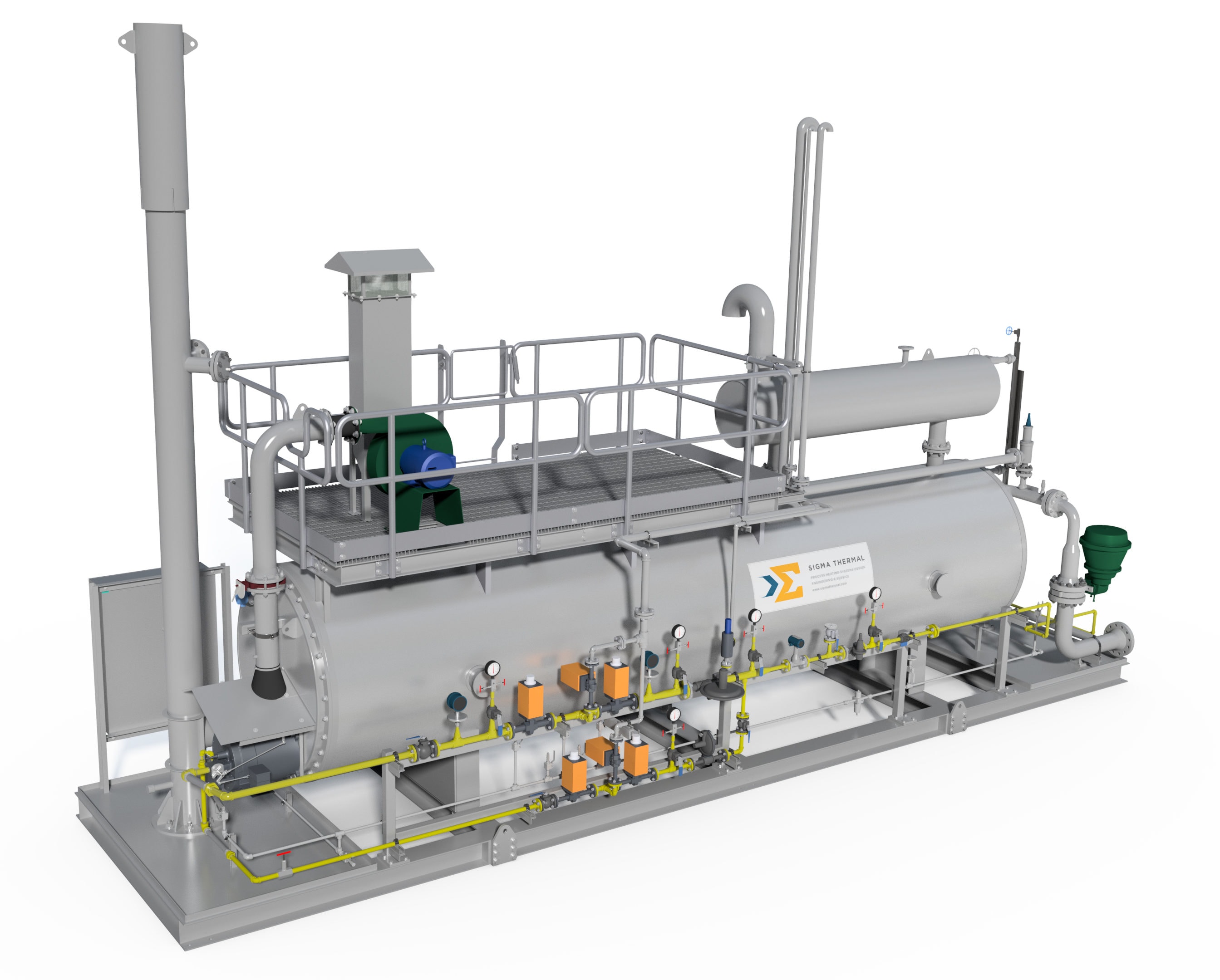

At Sigma Thermal, we offer a range of amine and glycol reboiler products, including process bath heaters, electric process heaters, and thermal fluid heating systems. Depending on your needs, we can help customers determine the ideal heater type and size for their amine or glycol reboiler system.

What are Amine and Glycol Reboilers Used For?

Often referred to as acid gasses, hydrogen sulfide and carbon dioxide gasses are present in varying quantities, depending on the well site and formation from which the gas stream originates. The maximum allowance of these compounds in the gas stream is guided by government regulations. To remove acid gas from the crude oil or natural gas stream, the stream is typically treated with an amine compound which absorbs the H2S and CO2. In the amine gas treating process, a reboiler is used to remove the acid gas and recycle the rich amine mixture into a clean stream that is again ready for processing.

Similarly, natural gas streams are treated with glycol to remove water from the natural gas prior to distribution.

How Do Amine and Glycol Reboilers Work in Natural Gas Purification?

Although amine and glycol reboilers both work to purify process streams, they do so using differing processes.

The Role of Amine Reboilers in Natural Gas Purification

Amine reboilers use the following steps to purify a natural gas stream:

- Step one. The natural gas is introduced to the system in the bottom of a tall vertical vessel known as the absorber. The amine is then introduced into the top of the vessel. The amine and gas come into contact with each other via trays or packing.

- Step two. The amine aborbs the H2S and CO2, and the purified natural gas exits from the top of the absorber. This is what’s known as an exothermic reaction. An adequately designed system will regulate the temperature to prevent the amine from absorbing the contaminants.

- Step three. Aftwerward, the amine is sent to the regeneration system, where it is filtered to eliminate any particles and heavy hydrocarbons entrained in the amine.

- Step four. Amine regeneration occurs in two pieces of equipment: the still and reboiler. The still is a vertical vessel containing trays or packing. The amine enters the top of the still, where it encounters the steam generated in the reboiler.

- Step five. Inside the still, the steam provides adequate heat needed to reverse the reaction and dilutes the H2S and CO2 released during regeneration. The increased temperatures and dilution shift the amine regeneration’s equilibrium point to higher amine purities.

- Step six. Lastly, the amine enters the reboiler, which is a shell-and-tube exchanger. Within the exchanger, steam or thermal fluid is used to generate the heat needed to vaporize a portion of water in the amine solution.

The Role of Glycol Reboilers in Natural Gas Purification

Glycol reboilers purify natural gas via the following process:

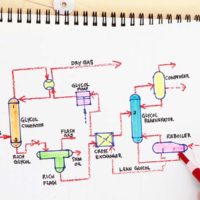

- Step one. At the beginning of this process, water-free glycol with a purity of over 99% is introduced at the top of the absorber, where it comes into contact with the wet natural gas stream. Through physical absorption, the glycol effectively removes water from the natural gas before it exits from the bottom of the column. Upon leaving the absorber, the glycol stream is typically referred to as “rich glycol.” The dry natural gas leaves the top of the absorption column and is introduced either to a gas plant or pipeline system.

- Step two. Once it has left the absorber, the rich glycol is directed into a flash vessel, where it undergoes a process to eliminate hydrocarbon vapors and separate any liquid hydrocarbons from the glycol. This step is crucial since the absorber typically operates under high pressure, which must be reduced prior to the regeneration step. Because of the rich glycol’s composition, a vapor with a high hydrocarbon content will form when the pressure is reduced.

- Step three. Once it exits the flash vessel, the rich glycol is heated in a cross-exchanger before being introduced to the stripper, or regenerator. They glycol regenerator consists of a reboiler, an overhead condenser, and a column.

- Step four. In the regenerator, the glycol undergoes thermal regeneration to remove any excess water and regain its high purity.

Why are Heating Systems Important for Amine & Glycol Reboilers?

In both of these processes, the respective fluid stream must be heated to a sufficient temperature to strip the acid gas or water without overheating the stream. Overheating of glycol or amines can cause significant degradation to the mixture and reduce the mixture’s ability to absorb the acid gas or water.

Direct fired systems, such as Weir bath heaters, can be used to heat the gas stream. Instead of the coil found in many bath heaters, a Weir bath heater contains a fire-tube with a weir at the end. This type of heater is used throughout the natural gas and crude oil processing industries due to its low maintenance and simplicity. The primary concern with a heater of this type is the direct contact between a very hot firetube and the circulated amine or glycol. Over time this exposure will cause thermal degredation of those chemicals, which require replacement once degraded.

Using indirect heating, like a thermal fluid heating system is an ideal way to provide the constant heat needed to maintain the efficiency of the reboiler, while preventing overheating and degradation. Unlike direct fired heaters, such as the weir bath described above, the temperature that the amine or glycol sees is limited to the temperature of the thermal fluid system. This significantly decreases degredation concerns, and prolongs the life of the expsensive amine or glycol used in the system

Sigma Thermal can assist customers in selecting the ideal heater type and size for the amine or glycol reboiler system.

Learn More About Heating Systems for Amine & Glycol Reboilers

Amine and glycol reboilers are essential components in various industrial processes, particularly in the oil and gas, petrochemical, and chemical manufacturing industries. As an industry leader, Sigma Thermal provides process heating solutions tailored to suit the requirements of various applications. Contact us today or request a quote to learn more about our heating systems for amine and glycol reboilers.