Condensate Stabilizers

To introduce natural gas into the pipeline, the gas stream must meet requirements related to its stability and purity.

Coming from the ground, natural gas is a mixture of hydrocarbons, including volatile light hydrocarbons which can cause dangerously high vapor pressures in upstream processing equipment. To remove light hydrocarbons from the gas stream, condensate stabilizers are often used at the well site. The condensate stabilizer flashes the lighter gases off of the gas stream by closely regulating the temperature and pressure of the stream through the stabilizer. Using this method, volatile hydrocarbons can be recovered from the gas, while the heavier hydrocarbons are condensed and remain as a liquid for transport.

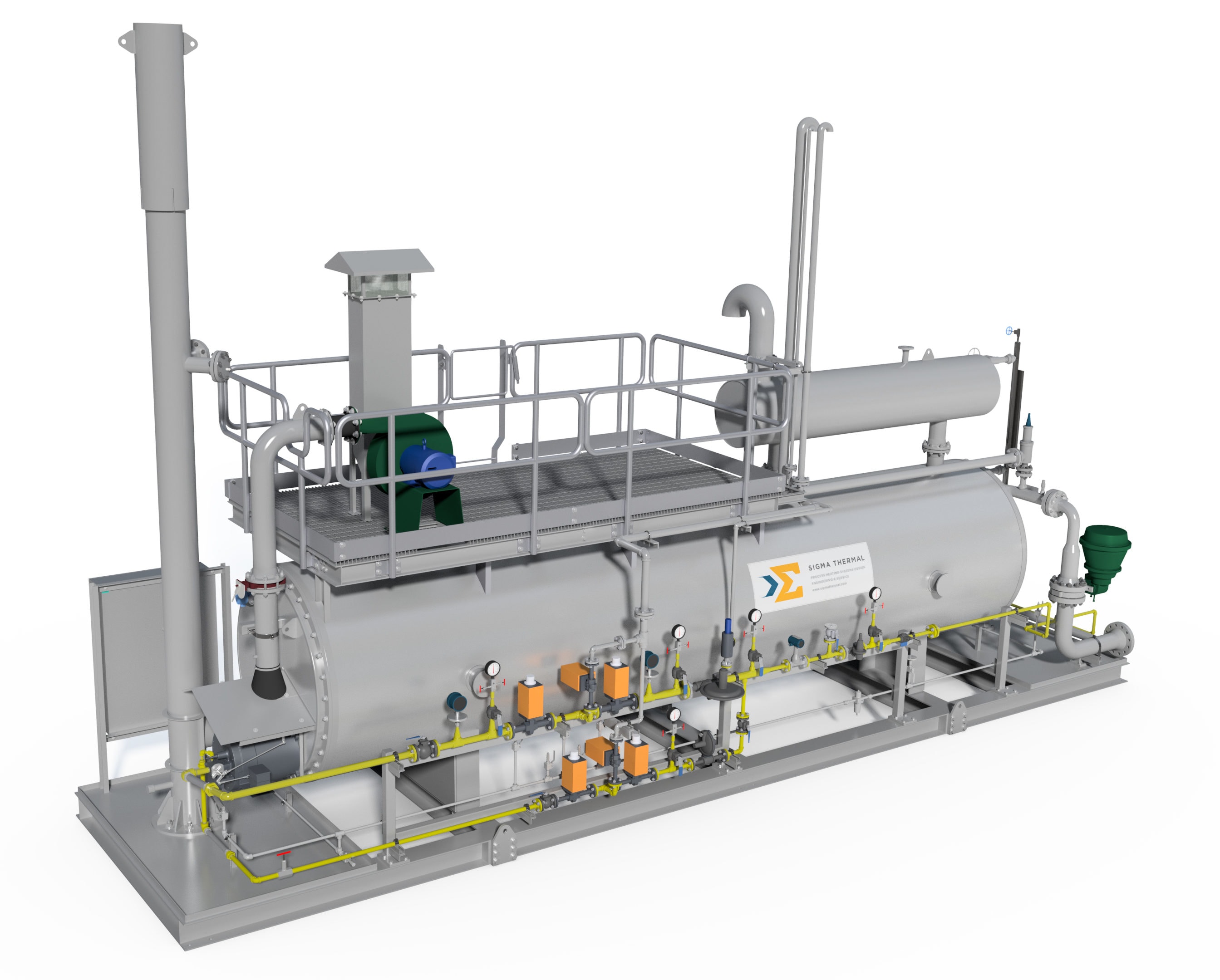

The gas stream can undergo multiple iterations of this operation, at varying temperatures, to separate the different gas streams such as ethane, propane, and butane, for market. These light hydrocarbons are collected in compressors for use elsewhere, while the heavy liquefied natural gas can be collected into tanks or fed into the pipeline, as desired. Heating for condensate stabilizer processes is typically performed using indirect systems like hot oil through heat exchangers, or electric heaters for electric heating, rather than direct-fired gas heating to reduce safety risks and environmental emissions. Sigma Thermal has a wide breadth of experience in creating heaters and skids for the oil and gas processing industries and can assist customers in selecting the optimal thermal system for their processing needs.