Gas Processing

Gas Processing

Gas processing depends on conditioning and heating solutions to ensure the gas maintains clean, acid-free, and temperature-controlled conditions. At Sigma Thermal, we design, engineer, supply, and service heating systems for the gas processing industry. Our heating engineers deliver standard and custom heating solutions and service existing heaters.

The Role of Heaters in the Gas Processing Industry

The gas processing industry relies on heaters to maintain the correct viscosity of petrochemical materials when processing in extreme temperature conditions. A popular heating option in the gas processing industry that performs this function is the immersion heater. Immersion heaters quickly and evenly heat tanks of liquid. The direct heating provided by the immersion heater delivers faster and more consistent heat dispersal.

There are several types of immersion heaters that the gas industry frequently relies on, including:

- Flanged Heaters: A solution for a uniform and moderate level of heating across heavy lubricants. The bitumen process relies on flanged heaters to improve the extraction process.

- Screw Plug Heaters: The ideal heater for smaller containers of liquid. They provide efficient heating using a hairpin tubular element brazed into a threaded pipe fitting, allowing it to fit into a threaded vessel or tank wall coupling. Screw plug heaters are also equipped with thermostats to maintain target temperatures.

- Pipe Heaters: Apply heat to the pipe rather than directly to the medium. Pipe heaters fit standard schedule 40 NPS pipes and resist extreme temperatures, highly viscous liquids like tar and wax, and corrosive chemicals.

- Over-the-Side Heaters: Inexpensive and practical solutions that come in various sizes and forms with a water-resistant terminal housing. They can also employ a thermowell to hold a temperature probe or tubular heating elements.

Line heaters preserve production efficiency in the gas industry. Line heaters prevent the formation of hydrates in oil field components by maintaining accurate process temperatures. Hydrates can cause bottlenecks within the system, and the obstruction can build up pressure within the line. They can also cause conduit failure, making prevention with temperature control a necessity. While line heaters are used in all environments, they are essential to oil processing in low-temperature environments.

Fired heaters are widely used in the gas processing industry. They are customized to specific applications and can use direct or indirect heat. Fired heaters can sustain process temperatures up to 1700°F and process pressures up to 3,000 psi. Manufacturers design fired heaters to ensure the environment, public, and employees are safe with high reliability and durability. They are vital to the marketing, transporting, refining, extraction, and exploration of petroleum products.

How Sigma Thermal Services the Gas Processing Industry

At Sigma Thermal, our precision heaters perform a critical service for the gas processing industry. We provide the following gas processing solutions:

- Fuel Gas Conditioning: Removes contaminants from gas that can lower efficiency and result in downtime.

- Regeneration Gas Heating: Manages temperatures to improve the drying efficiency of molecular sieves and other desiccant drying systems.

- Liquid Gas Vaporization: Changes the liquid state of the fuel to a gaseous state. It relies on high pressure and a heat exchanger that slowly raises the temperature of the liquid gas above 0 °C.

- Seal Gas Heating: Maintains the integrity of seals by keeping condensation from penetrating the seal wall. Condensed gas can cause the seal to lose pressure and leak.

- Condensate Stabilizers: Removes hydrocarbons from natural gas streams. It removes light and volatile hydrocarbonswhile leaving heavier hydrocarbons that can be condensed and incorporated into the liquid gas.

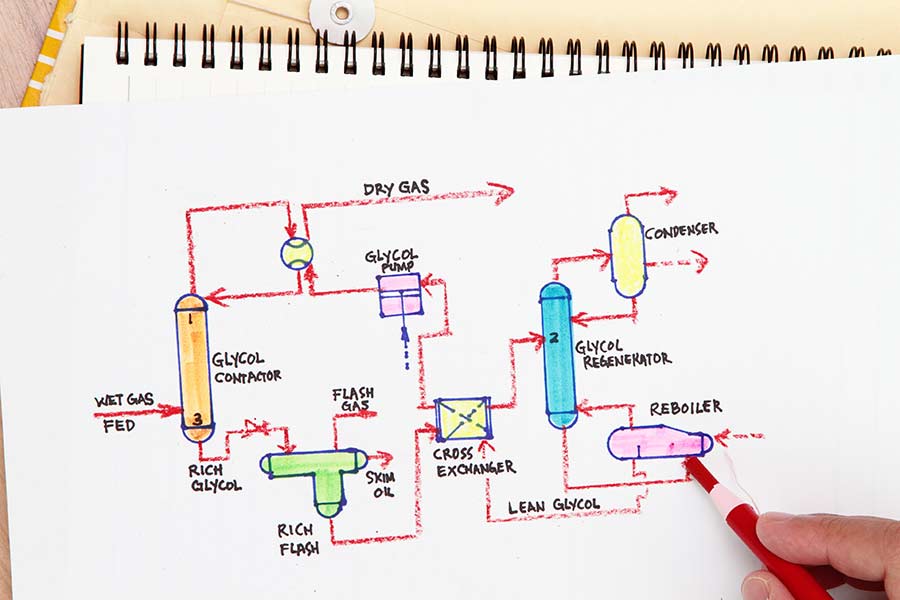

- Amine and Glycol Reboilers: Treats gas streams without overheating them. Amine or glycol is added to the stream and heated to remove acidic gases like hydrogen sulfide or carbon dioxide.

Rely on Sigma Thermal’s Heating Solutions

Heating systems and components are vital in maintaining ideal conditions for gas processing. At Sigma Thermal, we deliver custom solutions and services to suit your application. Contact us to speak with a heating expert or request a quote today.