Ovens & Fryers

For optimal efficiency, heating systems used in industrial food processing, such as ovens and fryers, must provide consistent, uniform temperatures to maximize quality and yields.

With the rising cost of energy, food processors are seeking ways to increase thermal efficiency to protect the already tight margins in this very competitive marketplace.

For industrial ovens, heating clean air and circulating it at tightly controlled temperatures maximizes throughput while improving the taste, texture, and appearance of baked goods. Temperature consistency in fryers provides the same benefits as in ovens and allows for reduced oil usage, further enhancing efficiency, and reduced oil degradation, preserving high quality taste.

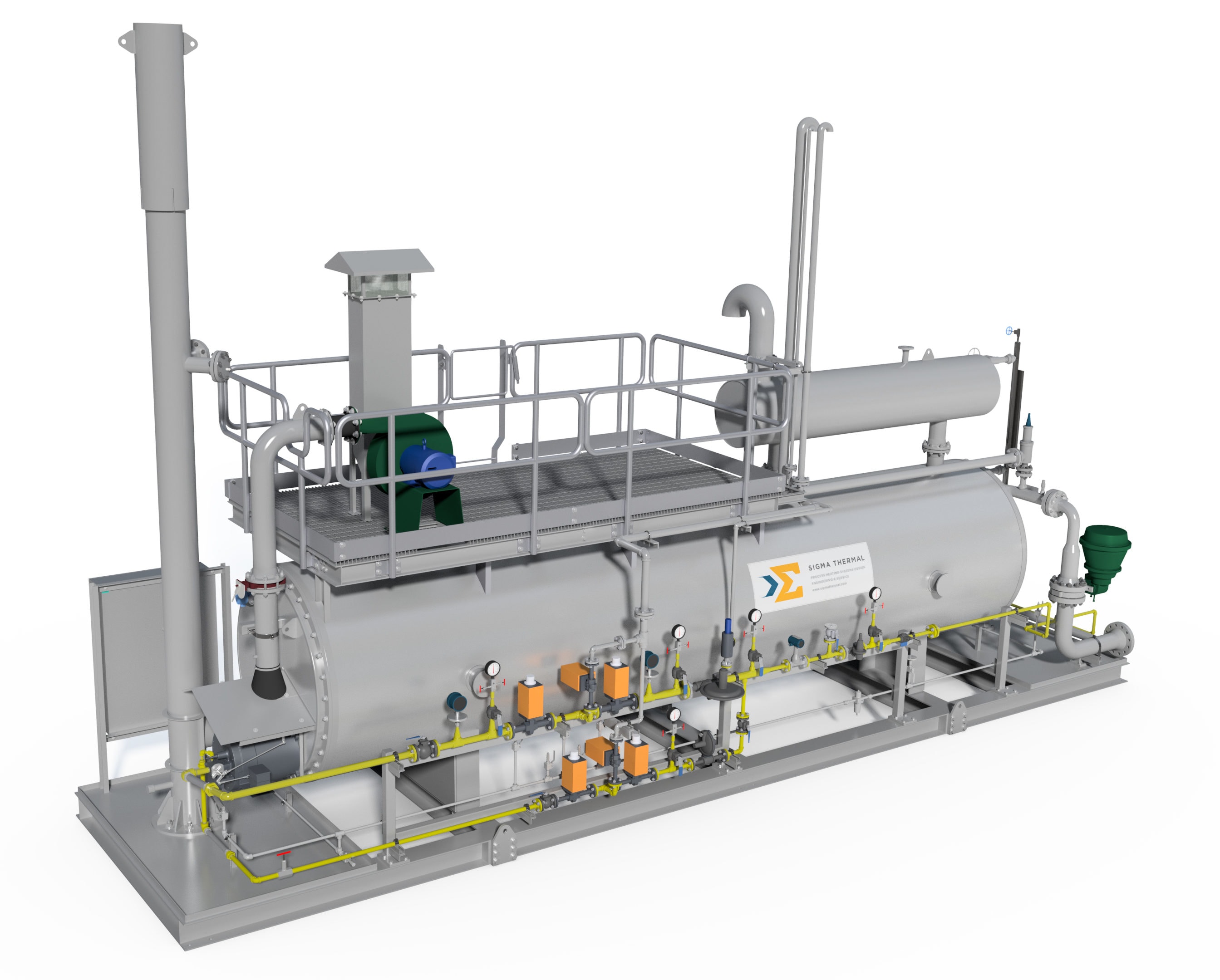

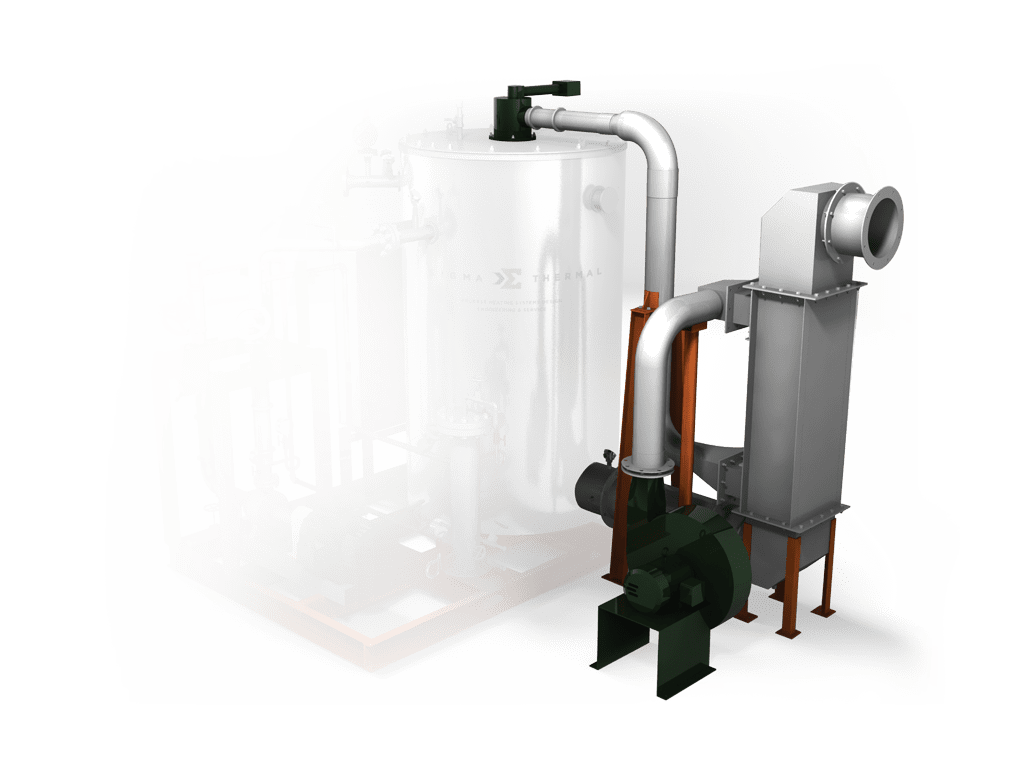

Sigma Thermal systems are used in many food processing applications which require an efficient heating system. These systems utilize oils for heat transfer; this means higher operating temperatures—generally up to 600°F with organic, FDA approved thermal oils. They also provide a greater measure of safety as they operate at lower pressures than other heating technologies, such as high pressure steam.

Sigma Thermal specializes in engineering complete heating systems for food processing applications. In continuous baking oven applications, we utilize multiple precision-controlled thermal zones that increase oven flexibility and control. When it comes to heaters and heating system control, Sigma Thermal can engineer a high efficiency solution that takes full advantage of cutting edge processes and advanced heating technologies.