Jacketed Vessels

Fluid management can be a sensitive business; whether dealing with chemical, food and beverage, or simply water for industrial processing, efficient and accurate liquid maintenance is crucial to an operation’s success.

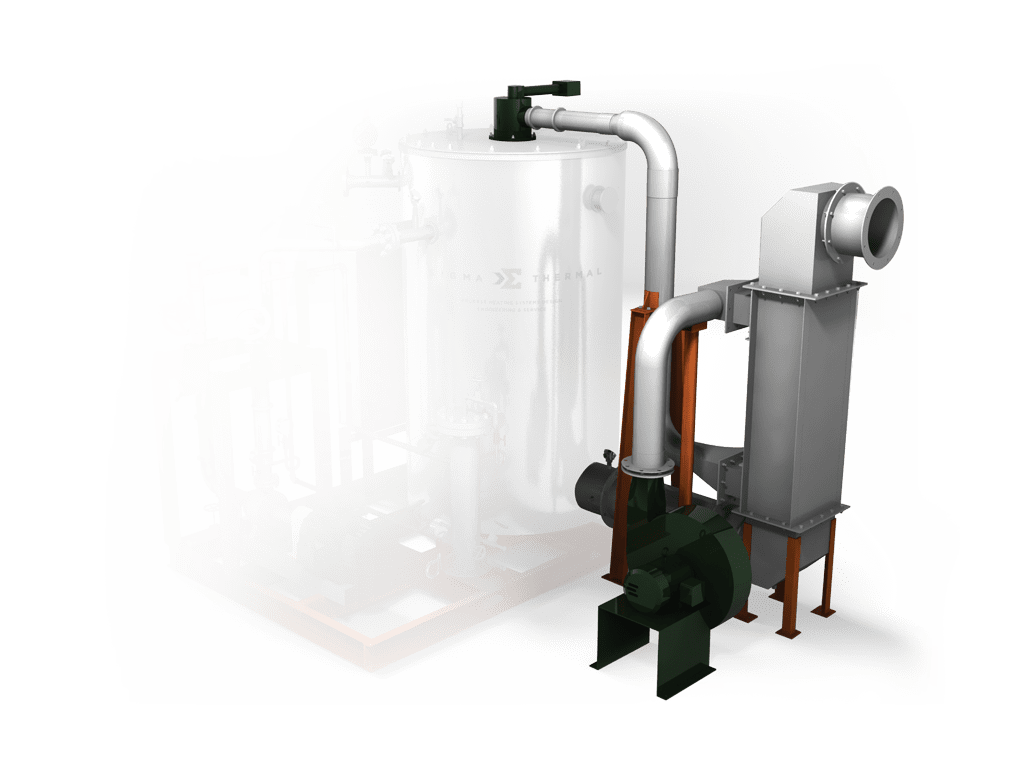

At Sigma Thermal, we craft custom thermal fluid heating systems to outfit tanks, vessels, heated molds, building heaters, autoclaves, reactors, and much more. Using thermal oil, glycol, and water as heat transfer mediums, these systems can be combined with a jacketed vessel for exceptional fluid management solutions.

What Are Jacketed Vessels?

Jacketed vessels and pressure vessels can be crafted in a wide assortment of styles to meet an operation’s particular processing needs. Put simply, a standard jacketed vessel introduces a secondary enclosure over a structural shell. The jacket creates a cavity to be utilized for heating and cooling management, usually by filling the space with a circulating fluid.

These systems create excellent heat transfer: they’re efficient, easy to control, and maintain excellent product quality. By introducing agitation in the jacketed vessels, it’s also possible to improve the homogeneity of the fluid properties, allowing for more consistent temperature or concentration levels.

Types of Jacketed Vessels

There are three main styles of vessel jackets available:

- Conventional vessel jackets offer a complete extra covering for all or part of the vessel. These are ideal for high-pressure applications and offer unique insulation benefits, creating both an inner and outer vessel wall. These jackets come in baffled and unbaffled styles, with agitating nozzles helping to improve turbulence and overall efficiency in the absence of baffles.

- Dimple vessel jackets utilize a light-gauge metal jacket affixed to the original vessel via spot or plug welds. This type of system offers strength and durability with minimal additional weight or expense, plus the advantage of natural turbulence as media flows past the dimple points.

- Half-pipe coil vessel jackets are preferred for high-temperature industrial processing applications. These jackets are also excellent for heat transfer and thermal fluid heating systems, particularly when the utility fluid is a liquid. These jackets can be divided into multi-pass zones for maximum flexibility.

Heat transfer efficiency can vary dramatically from one design to another and from one processing application to another. Generally speaking, a conventional jacket will demand greater shell thicknesses and engineered expansion joints to compensate for the stresses of thermal expansion, especially if the jacket and shell have been manufactured from different materials. For a thermal fluid heating system, dimpled jackets and half-pipe coil vessel jackets are typically the most efficient options.

Industries and Applications

The closed-loop heating system of a jacketed vessel allows for great convenience in batching processes. Many industries require that a vessel be both heated and cooled as part of a single process; a well-designed jacket with a thermal fluid system is a seamless way to achieve the necessary temperatures.

Glass-clad vessels and setups that require frequent cleaning also benefit from jacketed systems, as it’s difficult to equip such vessels with internal coils for heating or cooling. Below are just a few of the many industries benefitting from the convenience and reliability of thermal fluid heating in jacketed vessels.

- Chemicals and chemical processing

- Pharmaceuticals

- Food and beverage

- Milk and dairy

- Brewing and distilling

- Asphalt and roofing

Thermal Fluid Systems for Jacketed Vessels From Sigma Thermal

The team at Sigma Thermal is proud to offer a full range of thermal fluid heating systems for jacketed vessels and jacketed reactor heating and cooling applications. Our engineers can develop custom designs to fit any set of operating parameters, working closely with clients throughout every step of the process.

To learn more about our thermal fluid systems, or to discuss how Sigma Thermal can help with your next project, request a quote today.