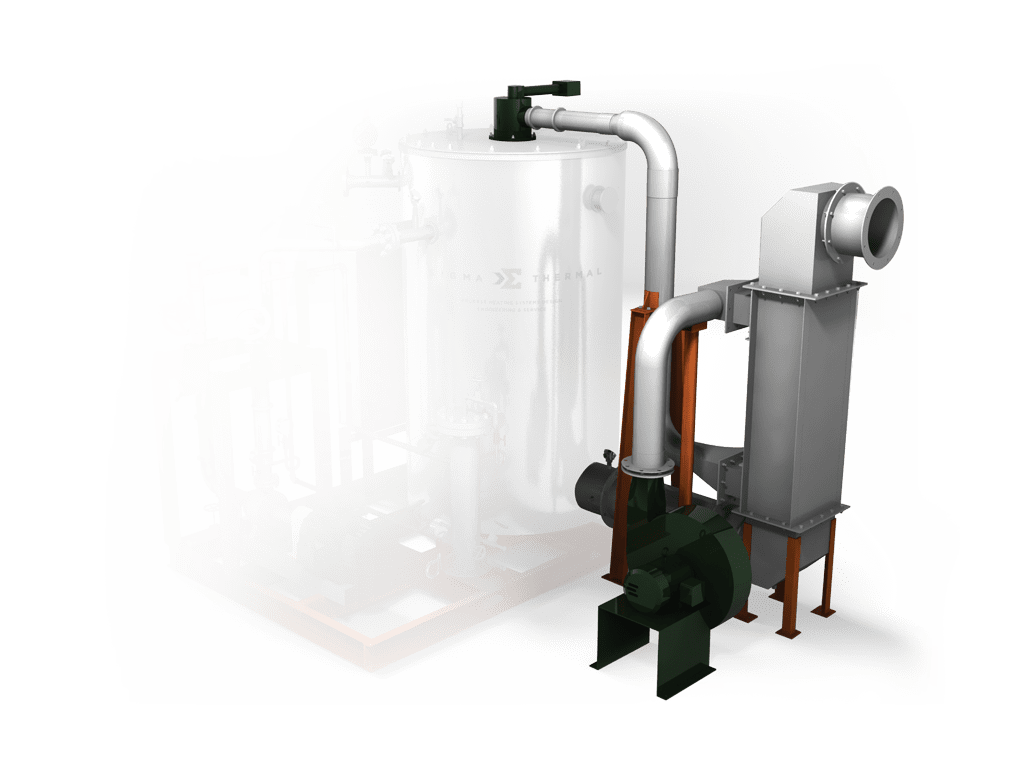

Tank & Suction Heating

Tank heating systems are key components for flow control, viscosity consistency, and protecting against frozen and broken pipelines. Energy efficiency and accurate thermal control are vital for maintaining process and material integrity, and Sigma Thermal manufactures process heating products in multiple configurations for tank heating and suction heating applications.

Suction heaters, designed specifically to heat material only as it is withdrawn, save substantial energy costs since overall heating requirements are considerably reduced. Sigma Thermal immersion heaters operate at near 100% efficiency while energy oil and water-glycol thermal fluid systems obtain high efficiency, especially at elevated temperatures for extended periods. Thermal fluid systems can be utilized in conjunction with immersion heat exchangers to provide a plant-wide tank heating solution. With decades of experience, Sigma Thermal engineers can guide you through the process of determining the optimal and most cost-effective system for your individual application.

Types of Tank Heating

Depending on your application’s requirements, there are two main types of electric tank heating available.

Direct Tank Heating

In systems using direct tank heating, the heater is in direct contact with the medium it’s heating. This is accomplished by either placing the heater directly inside the tank or circulating the fluid through the heater. The benefits of this type of heating include nearly 100% efficiency, accelerated heating, and the elimination of thermal lag. Subsequently, the system doesn’t involve any intermediate heat transfer medium that might otherwise cause a reduction in heat.

Indirect Tank Heating

Unlike the direct method, indirect tank heating uses a heat transfer medium to avoid direct contact between the heater and the heated medium. You have the option of using the tank wall as the heat transfer medium in these systems. One of the key advantages of indirect heating is that you can service the tank without any need to drain it beforehand. Additionally, you can reduce the exposure of watt density to the process fluid by more evenly spreading the heat across a greater surface area.

Direct & Indirect Tank Heating Products

There are a couple of different types of electric tank heating products that you can use.

Electric Immersion Heaters

One type of tank heating system you can install is an immersion heater. These heating systems require direct contact with the heated medium, which could consist of different types of liquids. These liquids may include water, viscous materials, solvents, oils, process solutions, and certain types of gases. Immersion heating systems also come with various temperature control options.

Electric Circulation Heaters

Another direct heating system you can use is a circulation heater. In these heating systems, the heater circulates the process fluid through the heater using either natural convection or a pump. Through the use of circulation heating systems, you can reduce watt density by spreading heat over a large heating surface. These are the ideal choice when there are space or watt density limitations. Circulation tanks can also be serviced without the need for draining, as long as the heater is properly valved and piped.

Based on your application’s specifications, you can use either of these direct tank heating systems to provide consistent and efficient heating for a wide range of mediums. At Sigma Thermal, we offer standard and custom immersion and circulation heaters designed to meet a variety of application requirements.

Thermal Fluid Heating Systems

Thermal fluid heating is a type of indirect heating in which a liquid phase heat transfer medium is heated and circulated to one or more heat energy users within a closed-loop system. Thermal oil, glycol, and water are common heat transfer mediums for these systems. In tank heating applications, finned pipe is installed inside the tank or around the tank to transfer energy from the heat medium to the product in the tank.

Tank Heating and Suction Heating Systems from Sigma Thermal

Sigma Thermal’s tank heating and suction heating products are built to last and meet CRN, ASME Section VIII Div I, and PED standards. We can provide complete solutions for a wide range of applications including process gas heating, asphalt, liquid vaporizer, high-temperature air, thermal fluid, water, and much more.

To learn more about our products and services, or to get started on your tank heating system solution, contact us or request a quote today.