Circulation Heaters

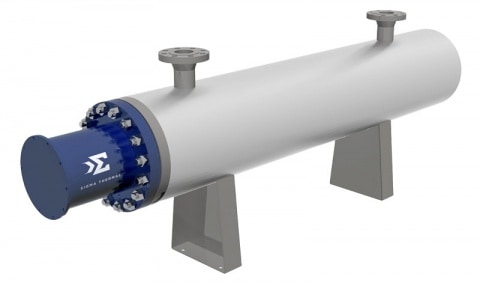

An electric process circulation heater is used as a conduit to facilitate the flow of process fluid directly over heating elements. Circulation heaters heat a variety of fluids from high-temperature gases to hard-to-heat liquids.

An electric process circulation heater is used as a conduit to facilitate the flow of process fluid directly over heating elements. Circulation heaters heat a variety of fluids from high-temperature gases to hard-to-heat liquids.

The heating elements, vessel, terminal connections, and mounting structures are packaged for quick installation. Heaters may be installed horizontally, vertically, or even sloped for vaporizing liquids.

Design Features

Mounting

Mounting options include saddles, skirts, mounting blocks, mounting lugs, legs, base plate, or a combination of two.

Nozzles

Multiple nozzles may be included as part of the heater. The inlet and outlet nozzles are placed so that the fluid is always flowing over the heated sections of the elements. Optional nozzles include vents, PSV connections, and drains.

A temperature sensor may also be placed on the inlet nozzle, outlet nozzle, or both for process control. Temperature sensors include a thermowell that may be NPT, socket welded. This is the perfect solution for the job where “plug and play” is desired.

Let Sigma Thermal mount and prewire the heater and panel on a common skid base. All that is left is the power supply and connection pipe. The easiest way to have your heater up and running in no time. We will even come and help you start it up.

Materials

Circulation heaters are available in a variety of materials, including carbon steel, low-temp carbon steel, 300 series stainless steel and nickel-based materials. Gaskets and bolting are selected based on process and design requirements.

Ratings

- Flange ratings from 150# to 2500#

- Raised face and RTJ flanges

- Clamp-type connectors available

- 3000# and 6000# NPT and socket weld

Corrosion Protection

Corrosion protection includes coating per Sigma Thermal standard specification or customer-specific specification.

Pumps

A pump can be added to any circulation heater. Whether pumping water, oil, or process liquid, let Sigma Thermal deliver the complete solution.

Approvals

- ASME Section VIII Div. 1 CRN PED

Typical Applications

Circulation heaters are utilized in various industries and applications to heat fluids as they flow directly over the heating elements through the system. They can be used for both pressurized and non-pressurized gases and liquids. Typical uses include:

- Jacketed reactor heating & cooling. Jacket reactors often must achieve and maintain processing temperatures up to 800° F to ensure proper functionality. In some cases, a circulation heating system is integrated into the jacket to ensure controlled reactor temperature.

- Molding & extrusion. Molding and extrusion operations require accurate and precise control over temperatures to ensure the production of quality pieces. Circulation heaters help monitor and adjust temperature conditions as needed.

- Molten salt operations. Molten salts are used for thermal energy storage and other high-temperature industrial processes. They can serve as the thermal medium in circulation heating systems, receiving heat from the system and feeding heat into the system.

The above list is not all-inclusive. Circulation heaters can be employed for many other industrial operations, such as:

- Catalyst activation and dehumidification

- Caustic solution heating

- Fuel oil/lube oil preheating and heating

- Process gas heating

- Steam superheating

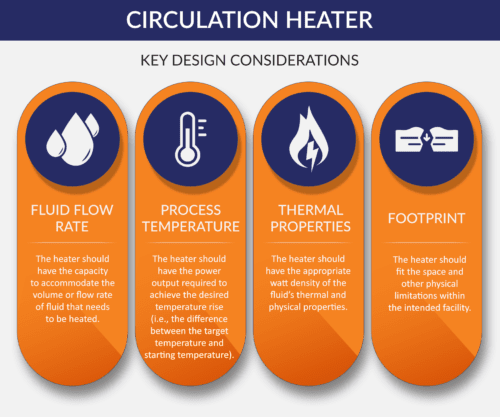

Key Design Considerations

There are many factors to consider when choosing a circulation heater for an application. Four of the key design elements to keep in mind to ensure that the equipment fully meets your needs are:

- Fluid Flow Rate. The heater should have the capacity to accommodate the volume or flow rate of fluid that needs to be heated.

- Process Temperature. The heater should have the power output required to achieve the desired temperature rise (i.e., the difference between the target temperature and starting temperature).

- Thermal Properties. The heater should have the appropriate watt density of the fluid’s thermal and physical properties.

- Footprint. The heater should fit the space and other physical limitations within the intended facility.

Circulation Heater Solutions From Sigma Thermal

Want to learn more about circulation heaters? Contact the Sigma Thermal experts today! To discuss your system requirements and restrictions with one of our representatives, request a quote.