Liquid-Gas Vaporization

Many gas products (hydrocarbon and non-hydrocarbon based) are transported and stored at low temperatures.

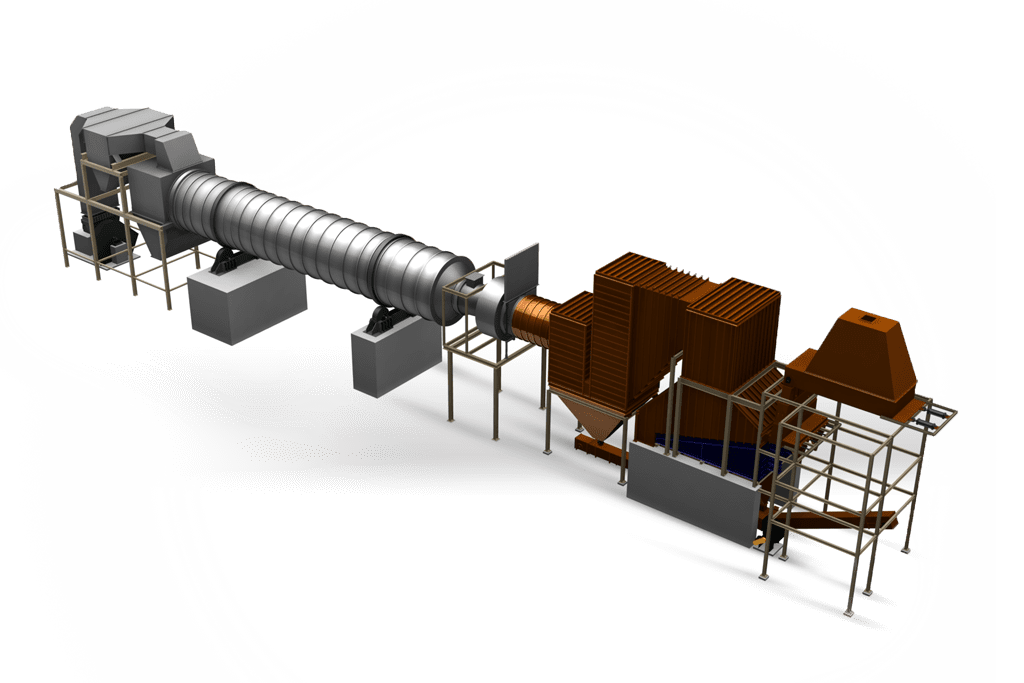

The liquefied product must then return to its gaseous state to be fed into transmission and distribution grids. Common examples of these products are propane, butane, nitrogen, oxygen, and liquefied natural gas. There are several liquid-gas vaporization methods used. Selecting the optimum process depends on plant site location, climate conditions, and throughput capacities.

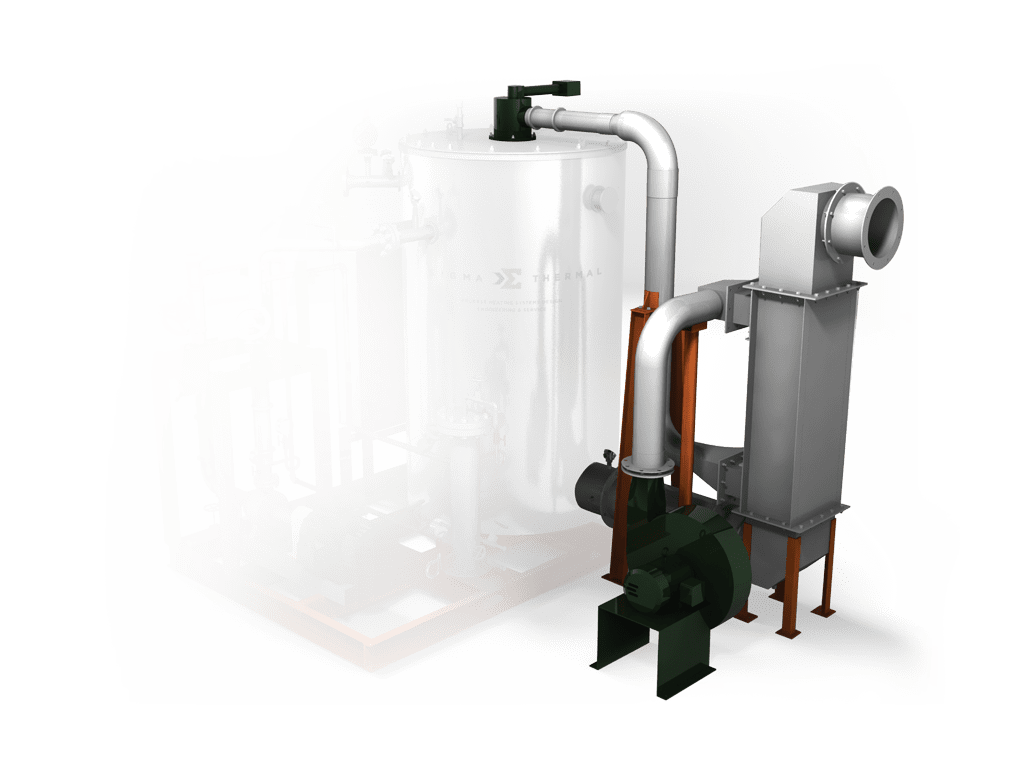

The vaporizing process typically takes place at high pressure using a series of heat exchangers to gradually warm the liquefied gas until its temperature rises above 0°C.

Depending on environmental conditions, various thermal fluid systems using glycol-water, hot oil, or hot water are all options for heating the gas to the desired temperature. With today’s high energy prices and concerns over the environment, closed-loop recirculation systems and waste heat recovery play an important role in conservation efforts for this and other gas production processes. Our engineers are experienced with a range of alternative solutions and offer insight into which is best for your application.