Molding & Extrusion

Precise temperature control is critical to the final quality of molded or extruded components.

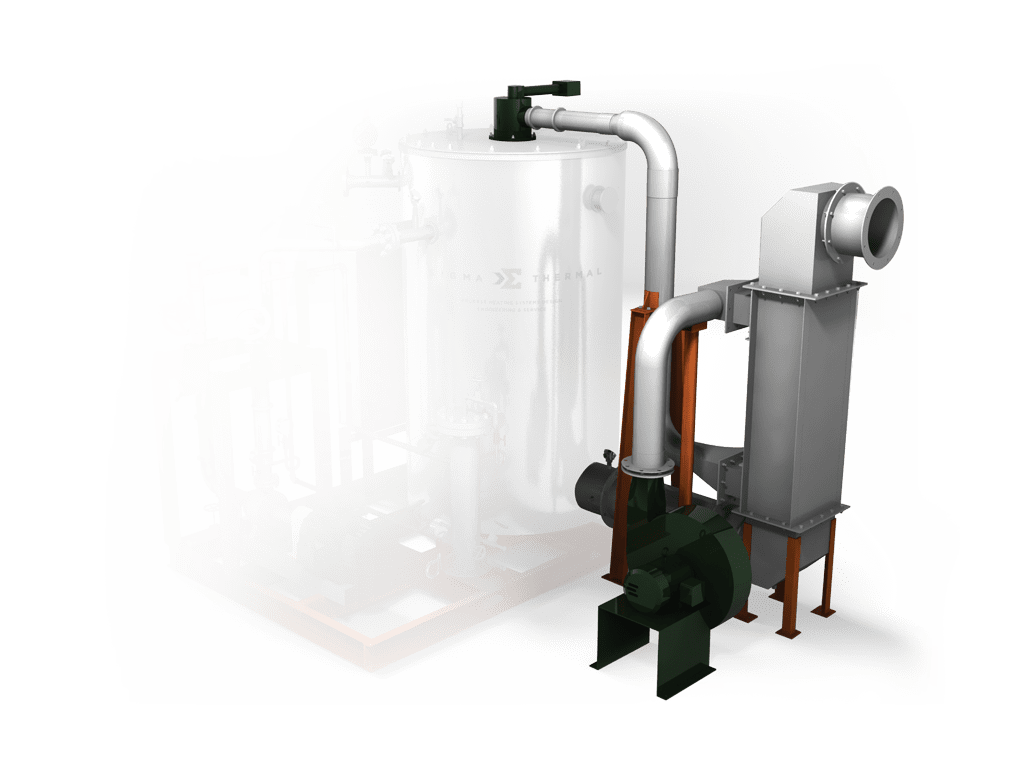

Not only must the resin be held at a specific temperature, the mold or extruder screw must be properly heated to produce accurate parts. Among temperature control options, closed loop thermal fluid systems are ideal for these applications, as they constantly monitor temperatures and are able to adjust heating and cooling rates based on feedback from the system. Thermal fluid systems are also safer to operate because they function at low pressures rather than the high pressures required by steam-based thermal systems.

Product and Services for this Application

Using organic oils, these thermal systems can be heated to 600°F while synthetic oils increase the maximum operating temperature as high as 800°F. These operating temperatures extend the system operating range well above what is typically required for most molding and extruding operations. At Sigma Thermal we engineer, fabricate, and service thermal oil systems in a number of standard configurations, as well as custom designs that are tailored to specific applications.