Dewpoint Heating (Joule–Thomson)

Natural Gas Dew Point Heaters

The temperature at which air becomes saturated with moisture is referred to as dew point. This means that in a saturated state the air is holding the maximum amount of moisture possible at its current temperature. Dewpoint heating increases the established temperature above the dew point to remove excess moisture content.

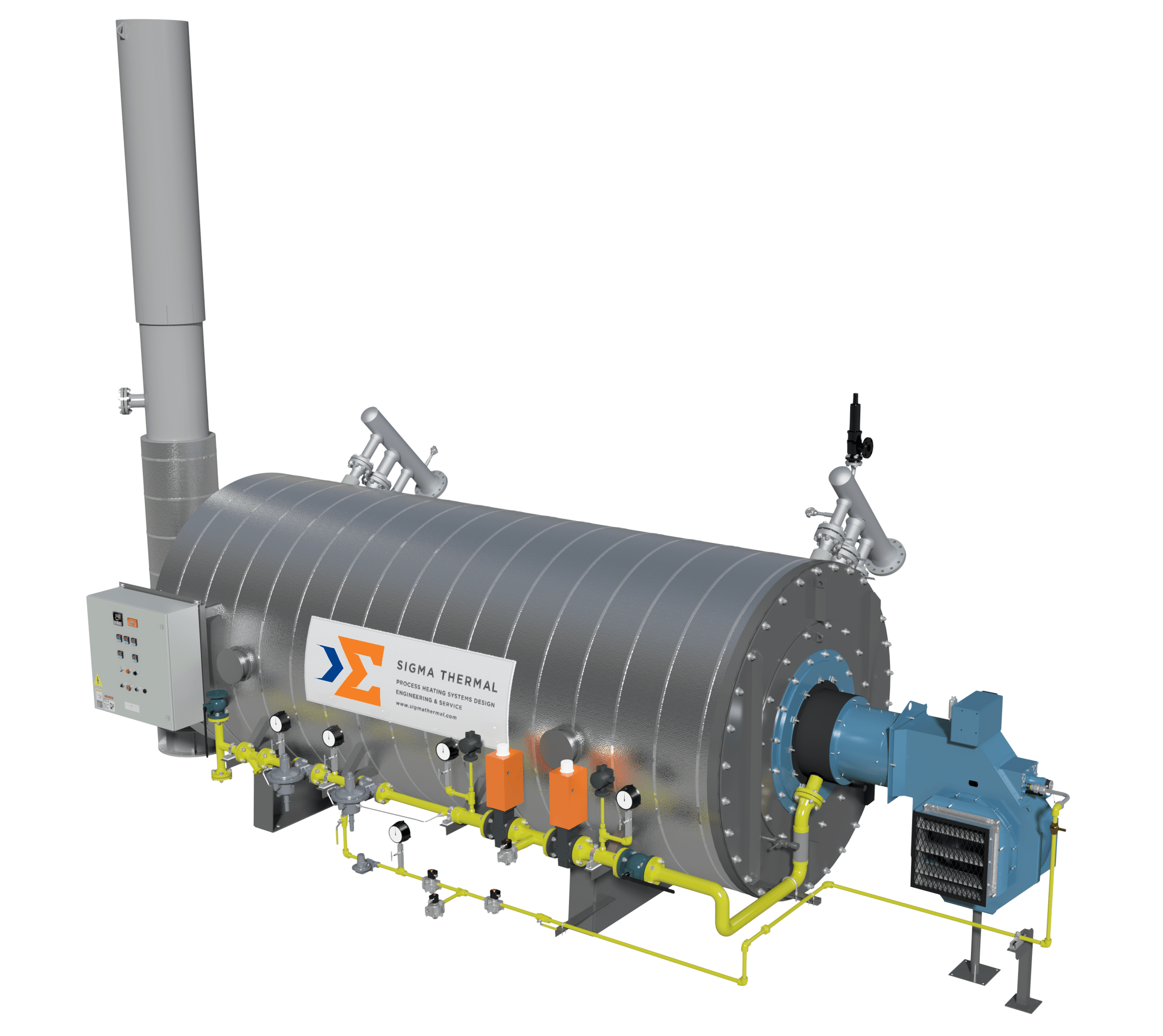

Dewpoint heating is a crucial component of fuel gas heating for gas turbines and power generation. Fuel gas often contains moisture and contaminants; therefore, dewpoint heating must be utilized as part of the fuel gas conditioning system to deliver clean gas (fuel) to turbines. Typical fuel gas conditioning systems include a fuel gas heater (also known as a dew point heater, or natural gas heater), pressure regulators, and coalescing filters.

Gas Turbines

Dewpoint heating ensures that water or fuel gas condensates do not enter the gas turbine, as they can damage the equipment. Moreover, dewpoint heating guarantees the gas is heated to the most efficient temperature before entering the turbine. During natural gas processing, fuel gases are pushed through a sophisticated network of pipelines from the location at which they originate to other locations where they are needed (i.e. turbines).

The gas must be highly pressurized to move efficiently through the pipelines. This means that the high pressure of incoming fuel must be reduced before it can be used at its destination. When the pressure of the gas is reduced, its corresponding temperature is also reduced; this is known as isenthalpic expansion or the Joule-Thomson effect. Depending on how much the pressure is reduced, water can condense, or in the case of a hydrocarbon, hydrate formation can occur. This occurrence can cause damage to equipment or devices downstream of the pressure reduction. One way to mitigate this is to heat the gas before the pressure is reduced. Therefore when the pressure is reduced, the temperature of the gas stays above the dewpoint or hydrate formation threshold.

Power Generation Demand

With rising power demands, anticipate that EPCs and OEMs will take longer to complete their project cycles. This makes it vital to coordinate the procurement of fuel gas heaters well in advance to avoid delays. Also, take note of some of the dewpoint heating challenges that arise when power demands increase:

• Lower efficiency fuel gas heater due to poor shell side heat transfer.

• Large fuel gas heaters that are existing, become even larger as power demand increases.

• Flow rates might vary, based on the number of turbines or auxiliary systems firing off the fuel gas.