Aerospace

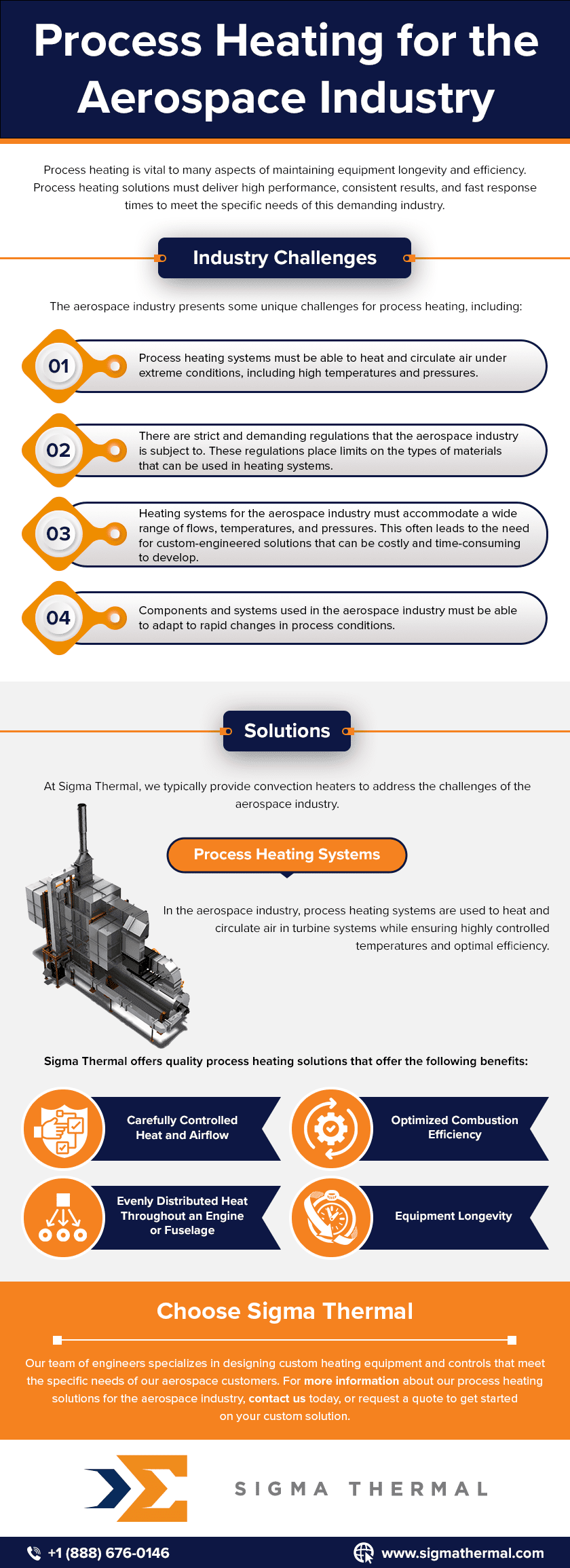

Process heating is vital to many aspects of aerospace, from maintaining equipment longevity and efficiency to conditioning fuel gas streams and keeping them free of impurities. Process heating solutions must deliver high performance, consistent results, and fast response times to meet the specific needs of this demanding industry.

Sigma Thermal provides efficient, reliable process heating solutions for the aerospace industry that can meet these challenges. We have a long history of providing high-quality products and services to our clients in this sector, and our experience enables us to provide the best solutions.

Industry Challenges

The aerospace industry presents some unique challenges for process heating, including:

- Process heating systems must be able to heat and circulate air under extreme conditions, including high temperatures and pressures.

- There are strict and demanding regulations that the aerospace industry is subject to. These regulations place limits on the types of materials that can be used in heating systems.

- Heating systems for the aerospace industry must accommodate a wide range of flows, temperatures, and pressures. This often leads to the need for custom-engineered solutions that can be costly and time-consuming to develop.

- Components and systems used in the aerospace industry must be able to adapt to rapid changes in process conditions.

Solutions

At Sigma Thermal, we offer process heating systems and fuel gas conditioning solutions that address the challenges of the aerospace industry.

Process Heating Systems

Process heating systems heat air and circulate it at tightly controlled temperatures to various process streams. In the aerospace industry, process heating systems are used to heat and circulate air in turbine systems while ensuring highly controlled temperatures and optimal efficiency. Sigma Thermal offers quality process heating solutions that offer the following benefits:

- Optimized combustion efficiency. By carefully controlling the heat and airflow, engineers can ensure that each aircraft engine operates at peak efficiency.

- Equipment longevity. By evenly distributing heat throughout an engine or fuselage, process heating helps to avoid hot spots that can cause premature metal fatigue.

Fuel Gas Conditioning Solutions

The main function of a fuel gas conditioning system is to keep the gas stream free of impurities that can cause problems downstream, such as failure, damage, or poor performance. These systems ensure that the gas is always in compliance and of the highest quality. At Sigma Thermal, we can provide quality fuel gas conditioning solutions that can meet your needs while providing various benefits such as:

- Improved combustion system performance

- Longevity of turbine combustion systems

- Decreased emissions

- Impurity-free gas streams

Learn more about fuel gas conditioning for combustion turbines here.

Choose Sigma Thermal

Sigma Thermal is a leading provider of process heating systems for the aerospace industry. We have years of experience designing, manufacturing, supplying, and servicing heating solutions for a wide range of applications. Our team of engineers specializes in designing custom heating equipment and controls that meet the specific needs of our aerospace customers.

For more information about our process heating solutions for the aerospace industry, contact us today, or request a quote to get started on your custom solution.