Regeneration Gas Heating

Regeneration gas heating technology is important in the oil, gas, chemical, and petrochemical industries.

High process temperatures must be managed as fluid streams, such as natural gas, and are fed into molecular sieve beds or other desiccant style drying systems. As desiccant systems become saturated, regeneration gas heaters dry the sorbent for the next cycle. Regeneration gas heaters are also frequently found in mole sieve applications within air separation facilities, where CO2 and water are removed from the ambient air prior to liquefying and fractionally distilling the air.

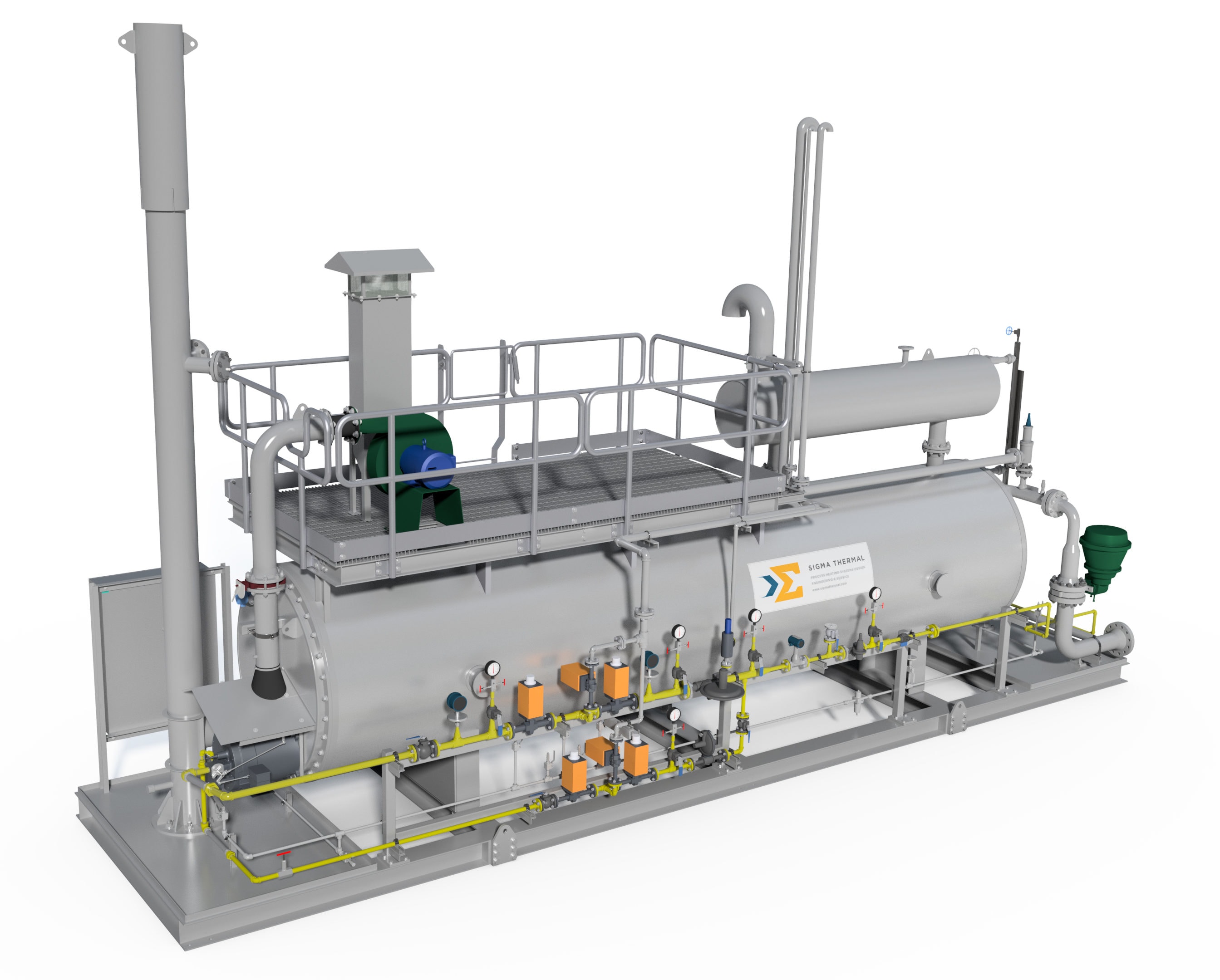

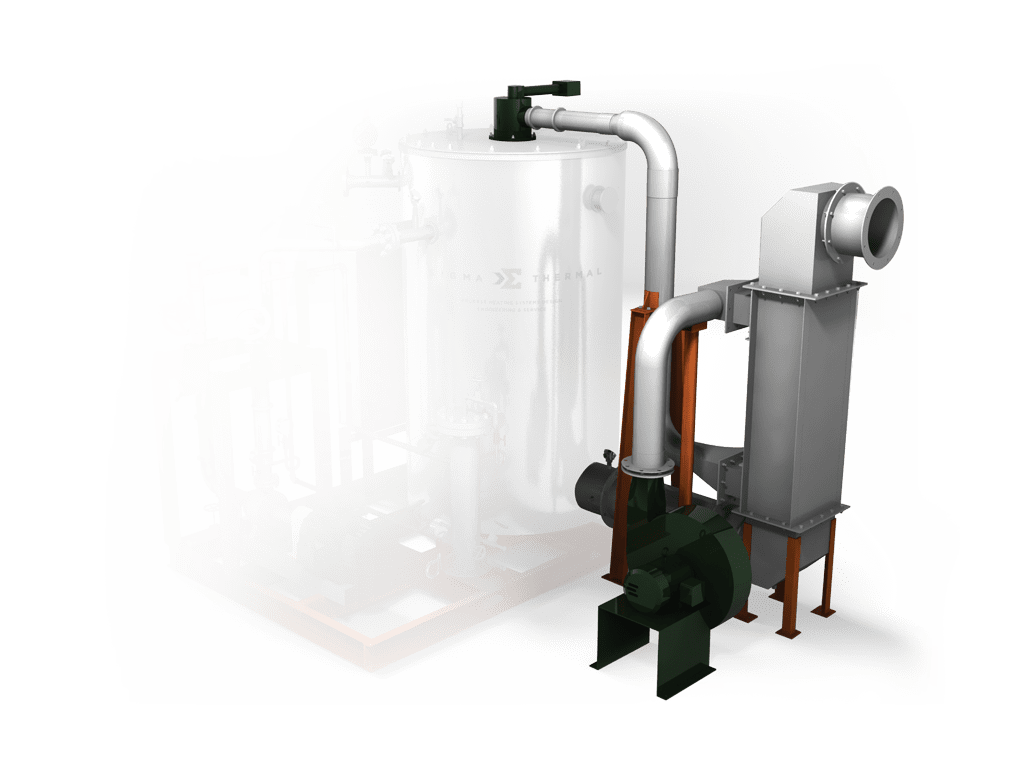

Choosing the right heating technology based on a detailed examination of process conditions can help to mitigate the danger associated with high heat sources in the vicinity of combustible substances for hydrocarbon regeneration gas applications. In air separation applications where the process pressures are very low, special attention must be given to tube wall temperatures to avoid tube failure during operation. Sigma Thermal manufactures high-performance regeneration gas heating systems using a variety of technologies, fuel sources, and burner options. Options include indirect systems like salt bath and thermal oil systems, as well as direct systems such as fuel-fired convection heaters or electric circulation heaters.