Viscosity Reduction

Sigma Thermal has been working with the oil & gas industry for many years, providing innovative heating solutions for many challenging applications.

We have developed a number of system designs for the purposes of heating heavy liquids, such as crude oil or crude oil derivatives. This process is often performed to reduce viscosity, and in turn increase the mobility of the fluid. Pumping heavy crude oil requires significantly more power when the oil is cold and viscous. Heating the oil to reduce the viscosity makes the oil much easier to handle. However, overheating crude oil can degrade the quality of the product, so care must be taken not to scorch the oil during viscosity reduction.

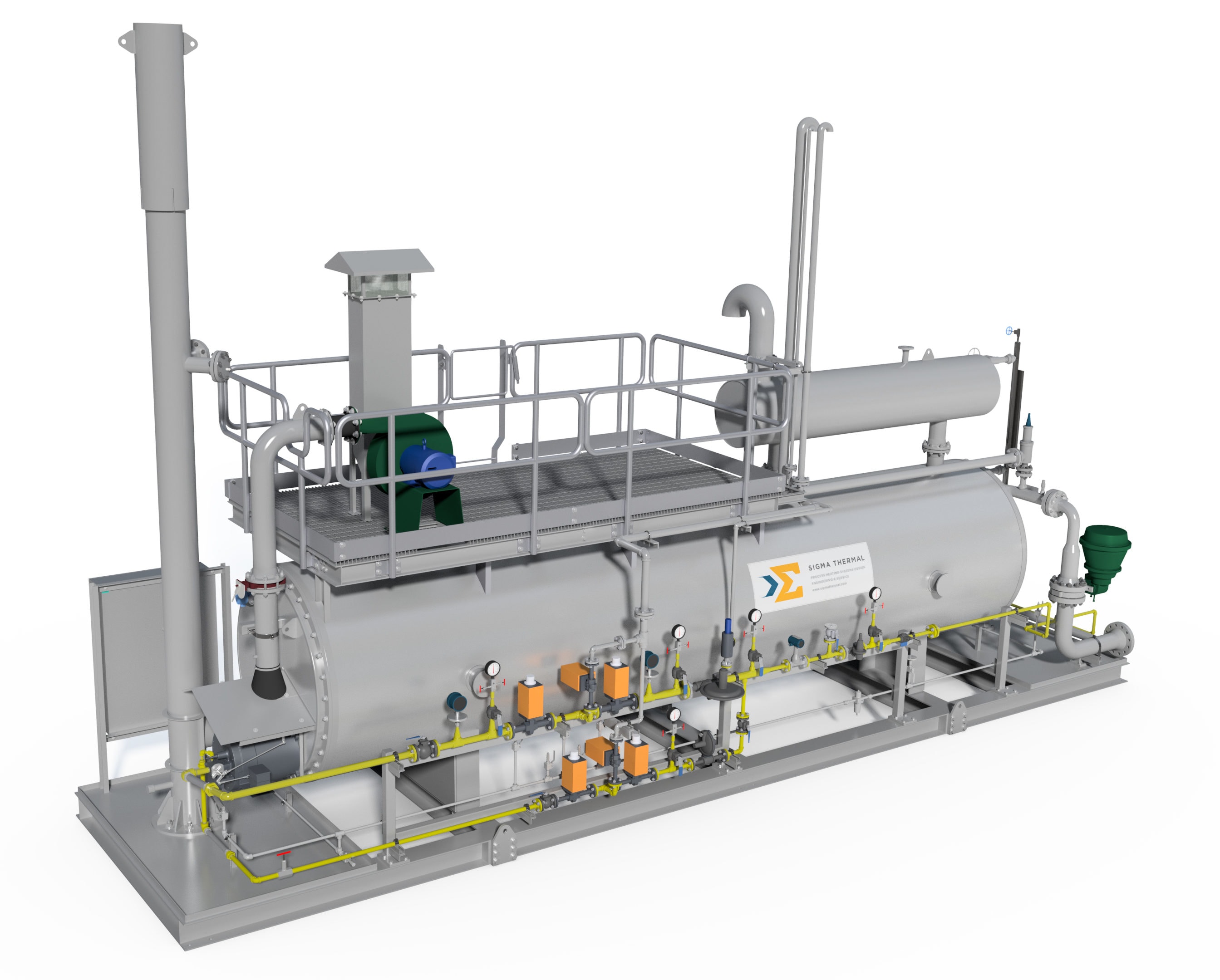

With the use of indirect heating, the oil is heated via a heating medium; it is never in direct contact with the tube wall, which ensures the oil does not become overheated. Because heating is required adjacent the well, skid systems can be employed which allow for applications in remote locations. These systems are designed to tightly control temperature, minimizing oil degradation and bring new levels of efficiency to this critical application.

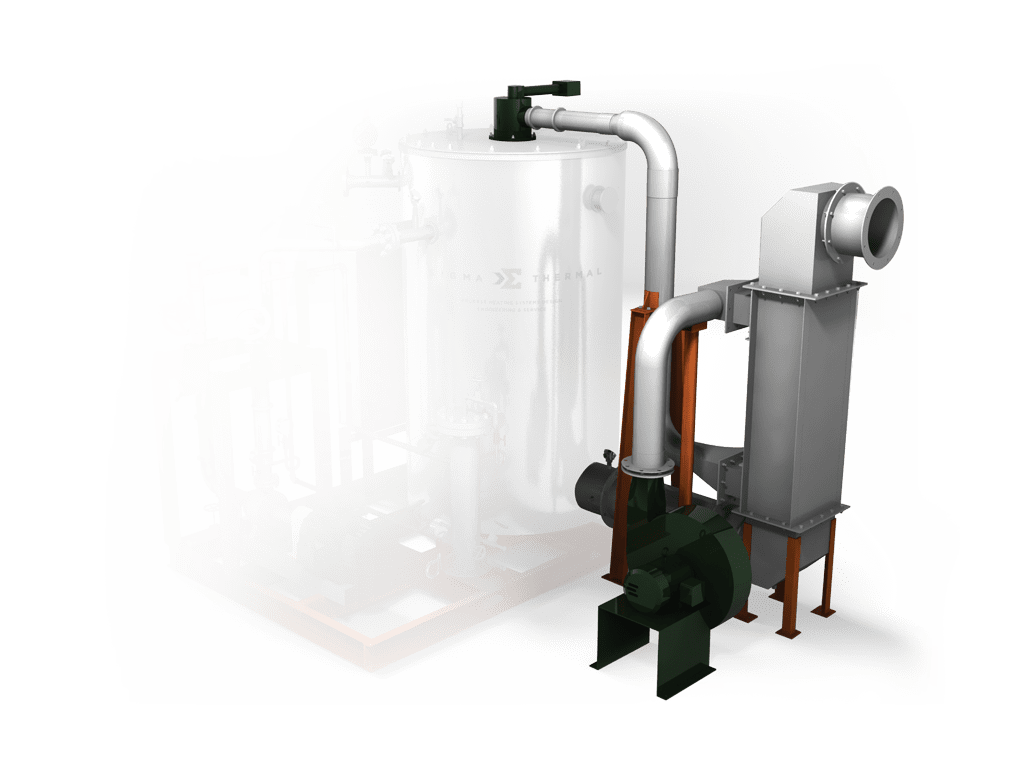

Direct heating of oil is also a common approach, and if managed properly can also be a good solution for heating crude oil. Low watt-density electric heating elements, and convection only style direct fired heaters are excellent ways to mitigate unintended degradation.