Heat Exchangers for Thermal Fluid Systems

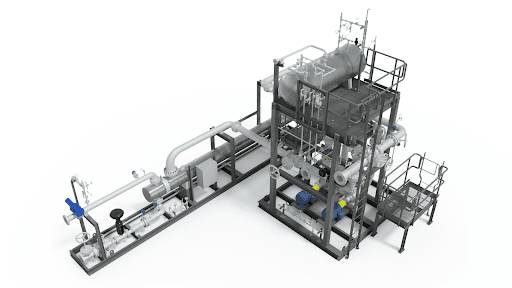

Sigma Thermal offers a range of thermal fluid heating systems in different sizes and types for specific applications. Thermal fluid systems use a medium – hot oil, water, or glycol, to transfer heat to the customer’s process often via a heat exchanger. These heat exchangers can be used for both heating and cooling operations.

Sigma Thermal offers a range of thermal fluid heating systems in different sizes and types for specific applications. Thermal fluid systems use a medium – hot oil, water, or glycol, to transfer heat to the customer’s process often via a heat exchanger. These heat exchangers can be used for both heating and cooling operations.

Due to the essential role they play, choosing the correct type of heat exchanger for your facility is vital to an efficient, fully functional thermal fluid heating system. Heat exchangers can enhance a system’s energy efficiency by repurposing heat where it is not required to other processes where it can be put to good use.

Find out more about the different types of heat exchangers, their respective advantages and disadvantages, and the main design considerations to weigh before selecting a specific product.

Applications

Heat exchangers are used for many heating and cooling operations, such as refrigeration, air conditioning, and space heating equipment. Common industrial applications include:

- Air heating

- Amine, glycol, and stabilizer reboilers

- Chemical reactors

- Commercial ovens and fryers

- Crude oil heating

- Heated presses, dryers, and kilns

- Indirect steam boilers

- Injection molding machines

- Natural gas heating

- Regeneration gas heating

- Suction heating

- Tank heating/tank farms

Types of Heat Exchangers

Based on the design requirements, there are different types of heat exchangers.

Shell and Tube Heat Exchanger

This is the most popular kind of heat exchanger on the market. It comprises a series of tubes enclosed in a larger cylindrical casing. The hot fluid can be on the tube side or the shell side, depending on the application. The tubes can be once-thru (single pass) or multi-pass, with the fluid on the shell side traveling via baffles to increase the heat transfer coefficients.

Advantages

- Widely understood across industries

- Versatile for use in many applications

- Comprehensive range of allowable temperatures and pressures

- Robust mechanical design

Disadvantages

- Has stagnant zones on the casing side that can cause corrosion

- Not suited for temperature cross conditions

- Can experience flow-induced vibration

- Can experience flow maldistribution

- Less thermal efficiency compared to other types

Plate Heat Exchanger

Plate heat exchangers work similarly to tube exchangers, but they use a series of stacked plates rather than tubes. The hot and cold fluids alternate between the plates to facilitate heating or cooling. Plates are more efficient than tubes because of their large surface areas and corrugated design. These exchangers are compact and often made from stainless steel, which makes them ideal for use in refrigerant and food and beverage processing systems.

Plate heat exchangers work similarly to tube exchangers, but they use a series of stacked plates rather than tubes. The hot and cold fluids alternate between the plates to facilitate heating or cooling. Plates are more efficient than tubes because of their large surface areas and corrugated design. These exchangers are compact and often made from stainless steel, which makes them ideal for use in refrigerant and food and beverage processing systems.

Advantages

- Suitable for significant temperature cross conditions

- Low upfront cost

- High efficiency

- Smaller, compact footprint

- Lower fouling

- Wide variety of configurations

Disadvantages

- Thin walls make material selection crucial

- Gasketed variations require particular closing and opening procedures

- Narrow range of allowable temperatures and pressures

- Narrow flow paths can lead to fouling

There are three types of plate heat exchangers:

- Spiral plate: Spiral plate exchangers are welded plate heat exchangers with two parallel curved metal plates. These plates create very high turbulent flow in a countercurrent flow system. They are versatile and can be used with highly viscous fluids without clogging.

- Plate and frame: Plate and frame heat exchangers are made of corrugated metal plates in reciprocal contact. There are four kinds of plate and frame heat exchangers based on how the plates are held together. These varieties are semi-welded, welded, gasketed, and brazed plate heat exchangers.

- Plate coil: Plate coil heat exchangers combine the features of tube heat exchangers and plate heat exchangers. They are made of tubular coils carrying a heat transfer fluid connected to a panel, plate, or wall that contains another fluid.

Design Considerations

All heat exchangers use the same basic principles of operation, but certain designs are better suited for specific applications. Here are some design considerations to take into account before selecting a heat exchanger.

All heat exchangers use the same basic principles of operation, but certain designs are better suited for specific applications. Here are some design considerations to take into account before selecting a heat exchanger.

Type of Fluid

The heat exchanger may have two or more heat transfer fluids. The specific types of fluids and their physical and chemical features help determine the flow configuration best suited for each application.

If corrosive, high-pressure, or high-temperature fluids are involved, the design must be able to withstand high-stress conditions throughout the cooling or heating process.

Objective

The desired thermal output and rate of heat exchange help determine the optimal heat exchanger design. Some heat exchangers can be designed to handle higher temperatures, though at a higher cost.

Flow

The flow configuration refers to the directions of fluid movement in the heat exchanger in relation to each other. Heat exchangers use four primary flow arrangements: cocurrent, countercurrent, crossflow, and hybrid flow.

Cocurrent flow heat exchangers are heat exchanging devices where fluids move parallel to and in the same direction as each other. Although this arrangement leads to lower efficiency, it also allows for more uniformity across the exchanger’s walls.

Countercurrent flow exchangers are designed such that the fluids move parallel but in opposite directions. It is the most popular flow arrangement, as it allows for a greater amount of heat transfer between fluids.

Crossflow heat exchangers are designed so that fluids flow perpendicularly to each other. The efficiency of this flow configuration falls between cocurrent and countercurrent flow heat exchangers. Hybrid flow heat exchangers combine the features of the previously mentioned flow arrangements.

Construction

The heat exchanger’s construction can refer to the following characteristics:

- Recuperative vs. regenerative: In recuperative heat exchangers, each fluid flows simultaneously in its channel within the heat exchanger. In regenerative heat exchangers, warm and cool fluids flow through the same channel.

- Direct vs. indirect: In direct contact heat exchangers, heat transfers through direct contact between one fluid and another. In indirect contact heat exchangers, the fluids are separated from each other through thermally conductive components, like plates or tubes.

- Static vs. dynamic: In a static heat exchanger, the components and material remain stationary as fluids flow through the exchanger. The components and material in dynamic heat exchangers move during the heat transfer process.

Size

Heat exchangers come in different shapes and sizes. A compact heat exchanger is the better choice for applications with limited space, such as in cars or airplanes. Make sure the spatial limitations of your facility can accommodate your chosen heat exchanger.

Costs

The cost of a heat exchanger includes not just the initial purchase price but also installation, maintenance, and operational costs. The best heat exchanger must fulfill the purpose of its application and be a worthy investment over the course of its lifetime.

Choose Sigma Thermal Process Heating Systems

Sigma Thermal offers a large selection of thermal fluid heaters and complete thermal fluid systems. Whether you require individual parts or need a whole system designed from scratch, our team can produce quality products according to your timeline. Purchasing a complete thermal fluid system from Sigma Thermal will ensure that your system operates at full capacity.

Contact us to speak to a thermal fluid system expert, or request a quote to start your order.

Resource Center

Our Blog

Understanding Thermal Fluids & Thermal Fluid Systems

Thermal Fluid Management • Advantages of Thermal Oil Heating Systems Types of Thermal Fluid Heaters • Work With Sigma Thermal The demand for process...

READ MOREEssential Components of Pre-Engineered Thermal Fluid Systems

As closed-loop systems, pre-engineered thermal fluid systems provide a source of heat for various industrial processes. They achieve effective and efficient heat transfer through...

READ MORE