Retrofits

Aftermarket Services: Retrofits, Upgrades, and Modifications

Sigma Thermal offers a variety of aftermarket services for process heating systems, including retrofits, upgrades, and modifications for system optimization. Whether your process heating system is manufactured by Sigma Thermal or another heater manufacturer, our retrofits/upgrade services can provide the support needed for optimal performance throughout the life cycle of your system.

Industrial process heating systems are our expertise and our goal is to create a partnership with you to help you determine the most beneficial upgrades or retrofits to enhance your system.

Potential Benefits

Investing in equipment retrofits or upgrades typically costs less than replacing the entire process heating system. Additionally, a fully optimized heating system results in increased efficiency, which can lower overall operating costs. Retrofitting existing plant equipment can be a challenge. To eliminate these frustrations, partner with Sigma Thermal to optimize your equipment or systems.

The benefits of retrofit or upgrade services:

- Extend the life of your equipment

- Increase equipment reliability

- Increase safety (plant & personnel)

- Meet standards and code compliance

- Increase asset value

Evaluating Your System

Our group of engineers help to make the decision process easy. They will collaborate with you to evaluate your needs, make recommendations, and then determine to implement the best solution(s) to specifically enhance your overall operation and extend the lifespan of your process heating system. Our experienced team can help you restore damaged systems, revitalize existing equipment, and upgrade to modern equipment to increase capacity.

At Sigma Thermal, we understand that retrofits or upgrades have to produce value that meets the goals of your operation. Therefore it’s important to determine the rate of return for your specific project. Sigma Thermal will help you assess profit or cost of the investment over a specified time, however if you want to get a general idea of what the rate of return will be for your potential retrofit or upgrade use the following:

Annual earnings from the sale of goods produced

(using plant assets)

Rate of Return = ___________________________________________

Value of plant assets

Common Retrofit Services

Sigma Thermal offers a selection of common retrofit services to meet a broad range of needs. These services include and are not limited to:

- Engineering/Site Audits. We perform site audits to identify possible retrofits and provide engineering to deliver the right solution.

- Process Improvements. Process improvement services to increase or decrease the capacity of industrial process heating equipment/systems to meet operational requirements.

- Efficiency Upgrades. Improve the efficiency of process heating systems with combustion air pre-heaters and economizer upgrades.

- Thermal Fluid Heating Systems. Improvement options for these systems include a range of custom solutions and the addition of temperature control loops, slip stream filtering systems, and pump skid assemblies.

- Replacements. Our team can replace equipment such as burner tubes, heater coils, and heater lids, and more.

- Heater System Modifications. We can modify existing process heating/oil systems with new heater lids, alternative fuels, and biomass hydraulic systems.

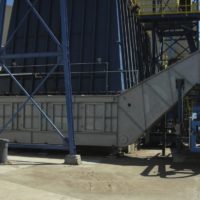

- Auxiliary Equipment. Integration of auxiliary equipment, including fans, burner and fuel train packages, piping assemblies, skidded equipment, drain and fill tanks, expansion tanks, and biomass conveying equipment.

Aftermarket Service Support

Aftermarket maintenance services, replacement parts, and retrofit/upgrade services, provide a range of cost-reducing and performance-enhancing benefits. Rely on Sigma Thermal’s aftermarket services for the support that you need to operate successfully. These resources are provided to make it easier to maintain and increase the uptime, efficiency, lifespan, and capabilities of your process heating systems and equipment. For more information retrofits/upgrades, or to learn about other aftermarket services, contact us or request a quote today.

Retrofit Services

Engineering / Site Audits |

|

Process Improvements |

|

Efficiency Upgrades |

|

Thermal Fluid Heating Systems |

|

Replacements |

|

Heater System Modifications |

|

Auxiliary Equipment |

|

Resource Center

Our Blog

Understanding Thermal Fluids & Thermal Fluid Systems

Thermal Fluid Management • Advantages of Thermal Oil Heating Systems Types of Thermal Fluid Heaters • Work With Sigma Thermal The demand for process...

READ MOREReclaiming Every BTU: The Ultimate Guide to Industrial Waste Heat Recovery

Industrial facilities release significant amounts of recoverable waste heat every day—energy that was purchased but not productively used. Much of it is lost through...

READ MORE