Services

Let us help you optimize your process heating equipment or system to ensure efficient performance.

Operating and maintaining process heating equipment is a serious undertaking. Safety, reliability, periodic maintenance, ever-changing codes, standards, and process needs are a challenge for even the most experienced facility managers.

Maximize uptime and increase profitability.

The good news is that Sigma Thermal offers complete support for all of your operations and maintenance needs. Whether it is service, technical support, training, parts, upgrades, or retrofits, you can rest easy knowing that you’re supported by qualified industry experts.

Reliable and Safe Operation

Prescheduled Maintenance Plan

Annual service plans for your process heating equipment or system are available to guarantee your system’s performance year in and year out.

Schedule your annual service appointment and receive:

- Prescheduled system audits (qualified Sigma Thermal technician)

- Locked rates on scheduled service for the duration of your service period

- Discounted pricing for replacement parts and components

- Priority response

- Non-contractual

System Analysis

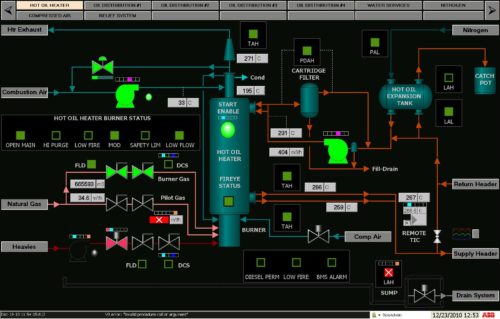

Our service department performs comprehensive process heating system inspections to identify areas of concern. A full-service report with performance data and recommendations is provided.

With each system audit, you can expect:

- Verification of safety and limit devices for proper operation

- Burner tuning for optimum efficiency and lowest potential emissions

- Control loop optimization for improved process temperature control

- Onsite training for operators and maintenance personnel

- Critical spare parts inventory survey

Technical Support and Training

Our service technicians are trained and have experience with a wide range of industrial heating systems. Technican assistance is available in person, by phone, or remotely.

Our team can also conduct comprehensive training sessions for plant supervisory, operation, and maintenance personnel. Training includes but is not limited to, system walk-downs for familiarization and observation of equipment.

Energy Efficiency

System Energy Audits

Our engineers and technicians are heat energy management experts. In addition to optimizing new and existing process heating systems to provide energy efficiency, our team also provides system expansion planning support.

Audits include:

- Waste heat energy potential

- Infrared casing scans

- Ultrasonic thickness testing

- Electrical systems inspection

- Boiler MACT compliance assessment

- Comprehensive service report (with data and recommendations)

More Aftermarket Solutions

OEM Replacement Parts & Components

Sigma supplies associated OEM parts and components that are essential to maintain and enhance process heating system performance.

- Replacement parts / Reliability assurance components

- Combustion air pre-heaters

- Heat recovery equipment

- Control panel upgrades

- Replacement heating equipment

- Boiler MACT compliance upgrades

Retrofits/Upgrades

Our engineers can assess your retrofit needs, suggest, and perform upgrades and modifications to optimize your process heating system’s performance. Retrofit/upgrades can also extend the life of your process heating equipment, increase safety for your plant and personnel, and help with meeting code compliance. Typical retrofit/upgrade services include:

- Thermal Fluid Heating System Customization

- Efficiency Upgrades

- Process Improvements

- Heater System Modifications

- Addition of Auxiliary Equipment