Periodic Plant Operator Training is Important

Process Heating System Operators Need Routine Training for Safe System Operation.

It is a well-known fact that operator error is a major cause behind many plant shutdowns and safety incidents. Plant operators have a direct impact on many aspects of plant operation and performance. Periodic operator training helps to ensure that operators are capable of operating equipment productively and safely. The blueprint for successfully operating process heating equipment includes routine operator maintenance training.

A Case for Maintenance Training

Incorrect system maintenance performed by under- or poorly trained personnel can potentially create unsafe operating conditions that lead to worksite events that cause injuries or even death. For instance, one local industrial company in Nebraska began to experience operation issues with a steam generator. Without having a full understanding of the underlying causes, their operators repeatedly reset the generator but failed to see any type of improvement.

Eventually, the generator exploded, and the entire top of the generator was blown off. The natural gas fuel train and piping to the burner was also ripped apart due to this event. Luckily, no one was hurt in this incident, but they easily could have been. After the explosion, the operator contacted Sigma Thermal; our technicians diagnosed the issue over the phone and led them through steps to get their system back online. If the operator would have known how to properly troubleshoot the equipment he/she could have avoided this event.

How Often Should Operators be Trained?

What happens when an operator abruptly leaves or retires from a manufacturing facility? In a number of industrial sectors, the absence of inexperienced operators and the presence of high turnover typically leads to a knowledge gap in many facilities. It can be hard to gauge whether current operators have the required knowledge to carry out their responsibilities safely. However, frequent operator training will ensure that all operators are up to date and informed about all aspects of the equipment, including maintenance.

What happens when an operator abruptly leaves or retires from a manufacturing facility? In a number of industrial sectors, the absence of inexperienced operators and the presence of high turnover typically leads to a knowledge gap in many facilities. It can be hard to gauge whether current operators have the required knowledge to carry out their responsibilities safely. However, frequent operator training will ensure that all operators are up to date and informed about all aspects of the equipment, including maintenance.

Depending on the complexity of the system being discussed, the frequency of operation, safety and maintenance training can vary. OEM providers of process heating systems typically recommend that onsite personnel receive training annually. Training sessions can last anywhere from a day to a week, depending on the complexity of the system. When is the best time to schedule these training sessions? To reduce cost, training sessions should be scheduled during routine system audits or maintenance visits.

Time and budget constraints can impact a company’s decision on how often training will occur. It is not uncommon for key personnel to have training sessions limited due to time constraints, nor is it unheard of for companies to postpone, cancel, or skip training to avoid costs associated with operator downtime. At the end of the day, the time and money that could be lost in the event of an accident should outweigh the potential cost of training.

Training Sessions Should Include…

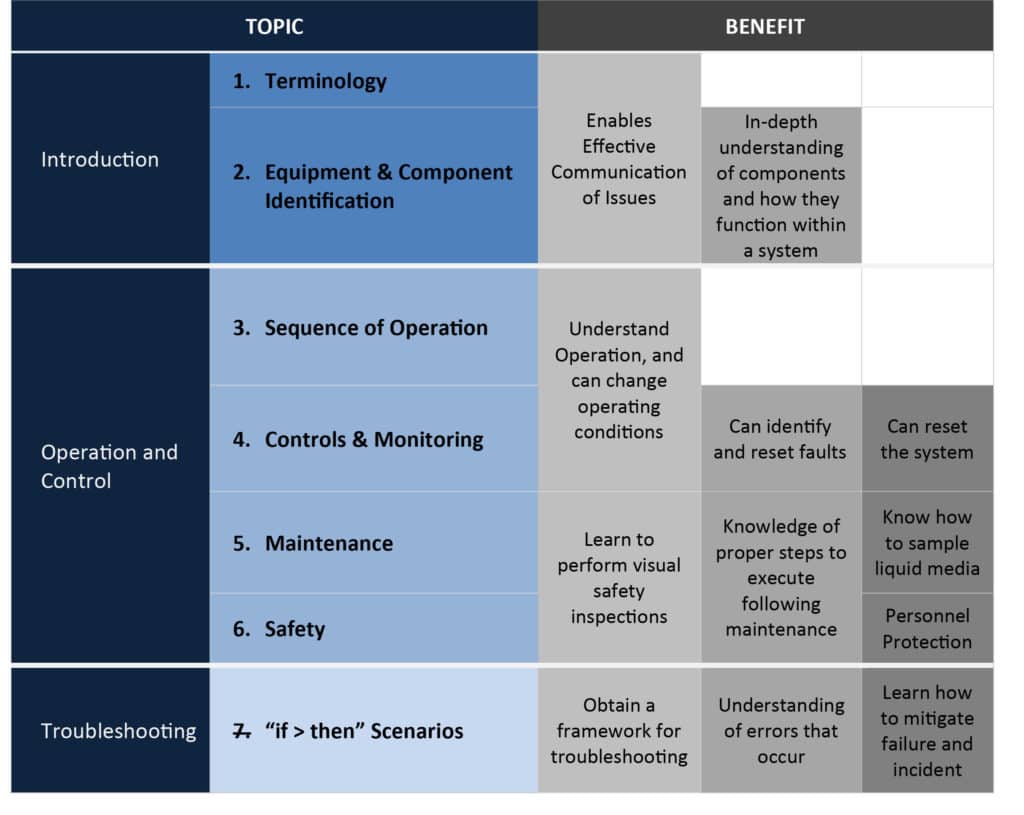

Generally, training sessions should include a system introduction, a summarization of system operation and control, safety, and a hands-on troubleshooting session.

Generally, training sessions should include a system introduction, a summarization of system operation and control, safety, and a hands-on troubleshooting session.

In reference to Process Heating Systems, during an introduction, personnel first gain an understanding of all relevant terminology and then they are trained to identify basic equipment and components. This intro allows them to develop a deeper understanding of how the system functions, and later down the road, it will help them communicate system issues more effectively during support calls.

Operation and control sessions cover startup and shutdown performance expectations and expectations for the process in its entirety. Operators are also trained to perform visual safety inspections, an essential function for safe operation. Additionally, all training includes a series of “if > then” scenarios; it is highly recommended to include live demonstrations of actual faults, if possible. “If > then” scenarios provide an excellent framework for troubleshooting and mitigation efforts and help personnel better understand the system.

Table 1A

Common Training Topics – Process Heating Systems

It should be noted that if high-level formal operator training is required, it should incorporate both classroom session and an exhaustive on-site walkthrough. Emphasis should be put on the on-site walkthrough, as this is where operation and maintenance personnel can realistically become familiar/refreshed with the equipment/system.

Requirements for Successful Training

Whether training is provided by the original equipment manufacturer or by personnel from within, there are several factors that need to be present in order for training sessions to be productive and worthwhile:

- Motivated Employees

- Real life Hands-On Scenarios / Visuals

- Repetition

- Sufficient, Dedicated, Quiet Training Time

- Concise Training Sessions (max of 1-2 hrs. per session)

- Momentum from Upper Management

Need to Schedule Operator Training?

Sigma Thermal offers annual training and maintenance services to owners of industrial process heating equipment and systems. As part of our commitment to our customer’s success, Sigma Thermal developed a Total Customer Care Program (TCCP) which combines these services for new and existing clients alike.

Sigma Thermal offers annual training and maintenance services to owners of industrial process heating equipment and systems. As part of our commitment to our customer’s success, Sigma Thermal developed a Total Customer Care Program (TCCP) which combines these services for new and existing clients alike.

Members of the program can preschedule annual appointments and Sigma technicians will travel to site for a comprehensive visit that cam include training, system inspection, maintenance assistance, efficiency evaluations and more.

Sign up for Sigma Thermal’s Total Customer Care Program today.

Contact Us

For more information about training and Sigma’s TCCP maintenance plan, contact us at 678-616-2820, or service@sigmathermal.com