Process Air Heating

Process air heating is of vital importance to many industrial operations.

In combustion turbine systems, air inlet heating is a key component for optimizing combustion efficiency and maintaining equipment longevity.

For large process facilities, Sigma Thermal offers heating systems that serve as a single user or plant-wide energy source for the distribution of air at individually controlled temperatures to multiple process streams. Typical examples of this type of system are water-glycol systems in SAGD (Steam Assisted Gravity Drain) facilities that are ideal for feeding heated air to once-through steam generators (OSTG), dew point heaters, and other process consumers within the facility.

Heating air and circulating it at tightly controlled temperatures is also essential in the large commercial ovens used by the food processing industry. At Sigma Thermal, engineered thermal oil systems can heat clean air and circulate it through multiple precision-controlled thermal zones with uniform temperature profiles. High temperature air heating at low pressures provides a large measure of safety along with significant efficiency for ongoing operation.

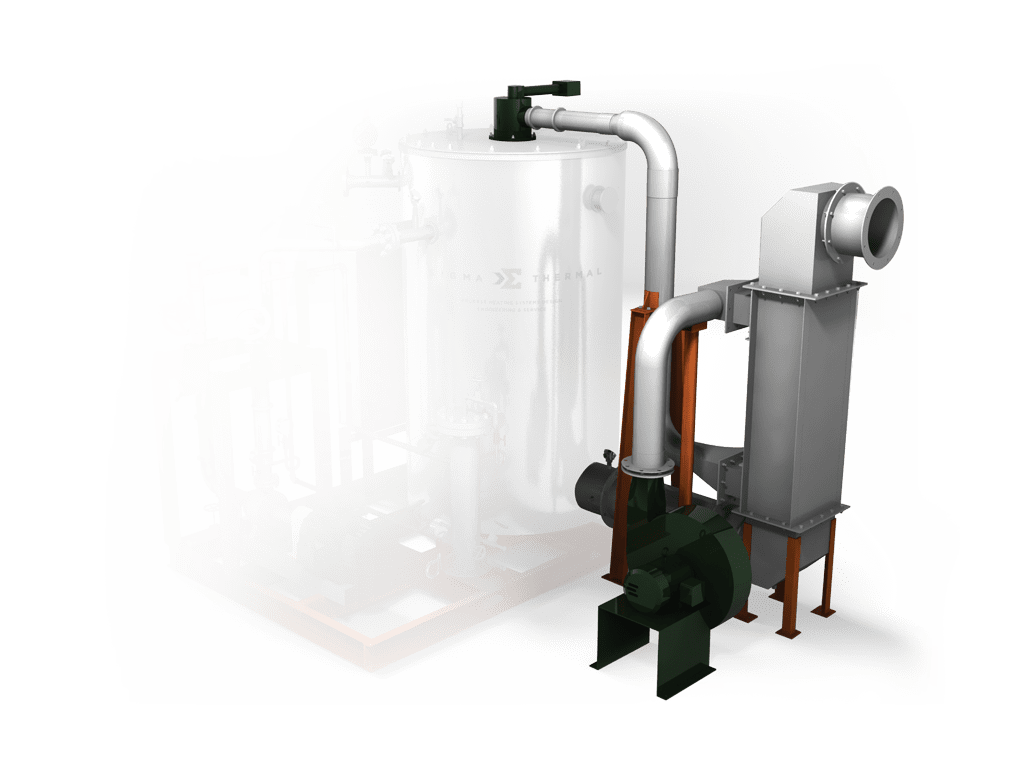

As an industry leading supplier of industrial process heating solutions, Sigma Thermal applies best practice methodologies to engineer systems that can meet virtually any technical and operational specification.