Case Study – Glycol Used in Potash Mining

Potash is a naturally occurring element of potassium-containing salts commonly used in manufacturing fertilizers. Nowadays, Potash comes from underground mining. The largest deposits are located in New Brunswick and Saskatchewan, Canada.

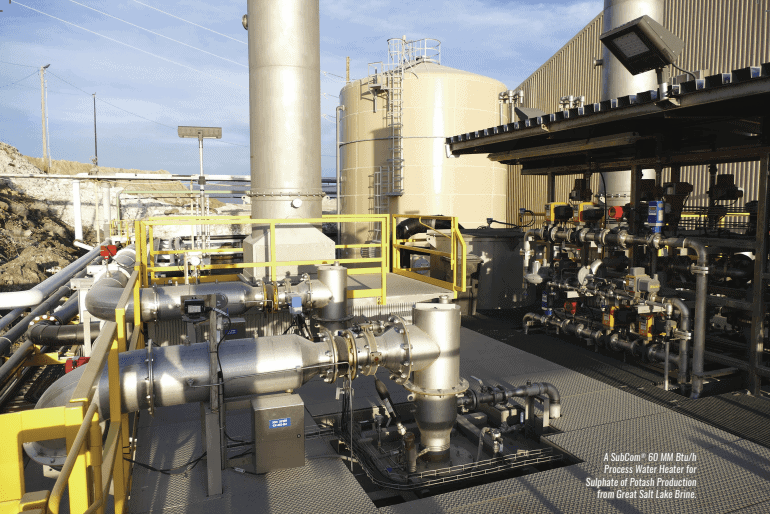

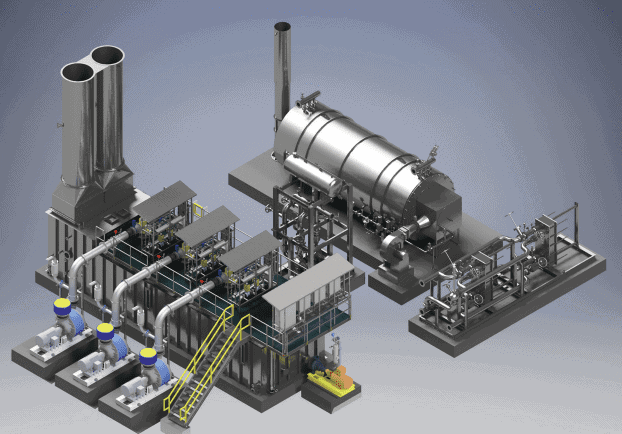

Sigma Thermal has been playing a significant role in creating innovative solutions for potash mining. Currently, one of Sigma Thermal’s innovations is being used for mining potash in Saskatchewan. This project utilizes Sigma Thermal’s glycol heater in conjunction with Inproheat Industries’ proprietary Submerged Combustion Technology known as SubCom. This article details more about Sigma Thermal’s glycol heat exchangers in Potash mining.

Case Explanation

Sigma Thermal’s exemplary innovation in potash mining came in full display through their partnership with other companies, such as Inproheater Industries in the Western Potash Corp Phase 1 project in Saskatchewan. SNC-Lavalin, an engineering consultancy for Western Potash Corporation, approached Inproheater Industries to create a heating system for the saturated, highly corrosive potash brine they were mining in Saskatchewan. The brine was supposed to be heated to a temperature of up to 110°C.

Since SNC-Lavalin was aware of Subcom’s abilities in the mining industry, they believed that it would be well-suited for use in their milestone project.

To maximize the efficiency of the mining process, Inproheat Industries brought on Sigma Thermal, and other companies, as trusted partners to produce essential components to help meet the requirements of the mining project. As a result, we presented our glycol heater to raise the heated brine from 82°C to the required 110°C range as it travels to the injection pumps.

The system also includes a Tranter Plate and frame heat exchangers to transfer the brine heat recovery over the injected brine. The system also incorporated a KSP pump to drive the heated brine through the brine-glycol heat exchanger to the injection pumps.

As a result of these innovations, the newly improved SubCom heating system generated up to $130 million in revenue from the Western Potash Milestone 1 project. This highly-efficient potash mining solution also delivered a low environmental impact and incurred a significant economic boost to Saskatchewan.

What Sigma Thermal HC2 Glycol Heater Has to Offer

With the use of Sigma Thermal HC2 Glycol heater, the SubCom potash mining system has become one of the most efficient potash mining systems worldwide. Its inclusion has achieved the following advantages in the use of SubCom:

- Lowering fuel, maintenance, and operation expenditure

- Guaranteed efficiency, which drives savings and shortens ROI paybacks

- Reduced fuel consumption

- Lowering greenhouse gas emissions and reducing carbon tax costs

Innovation Solutions from Sigma Thermal

The use of HC2 Glycol Heater is one of the many projects in which we’ve successfully delivered solutions for different industrial process heating systems. Our success is primarily driven by collaborations with our clients to ensure that we find the perfect solutions for their needs. By reaching out to us, you will benefit from our years of experience in industrial process heating systems and our team of dedicated experts. Contact us today and learn how we can help you.