Plant Utility Heating

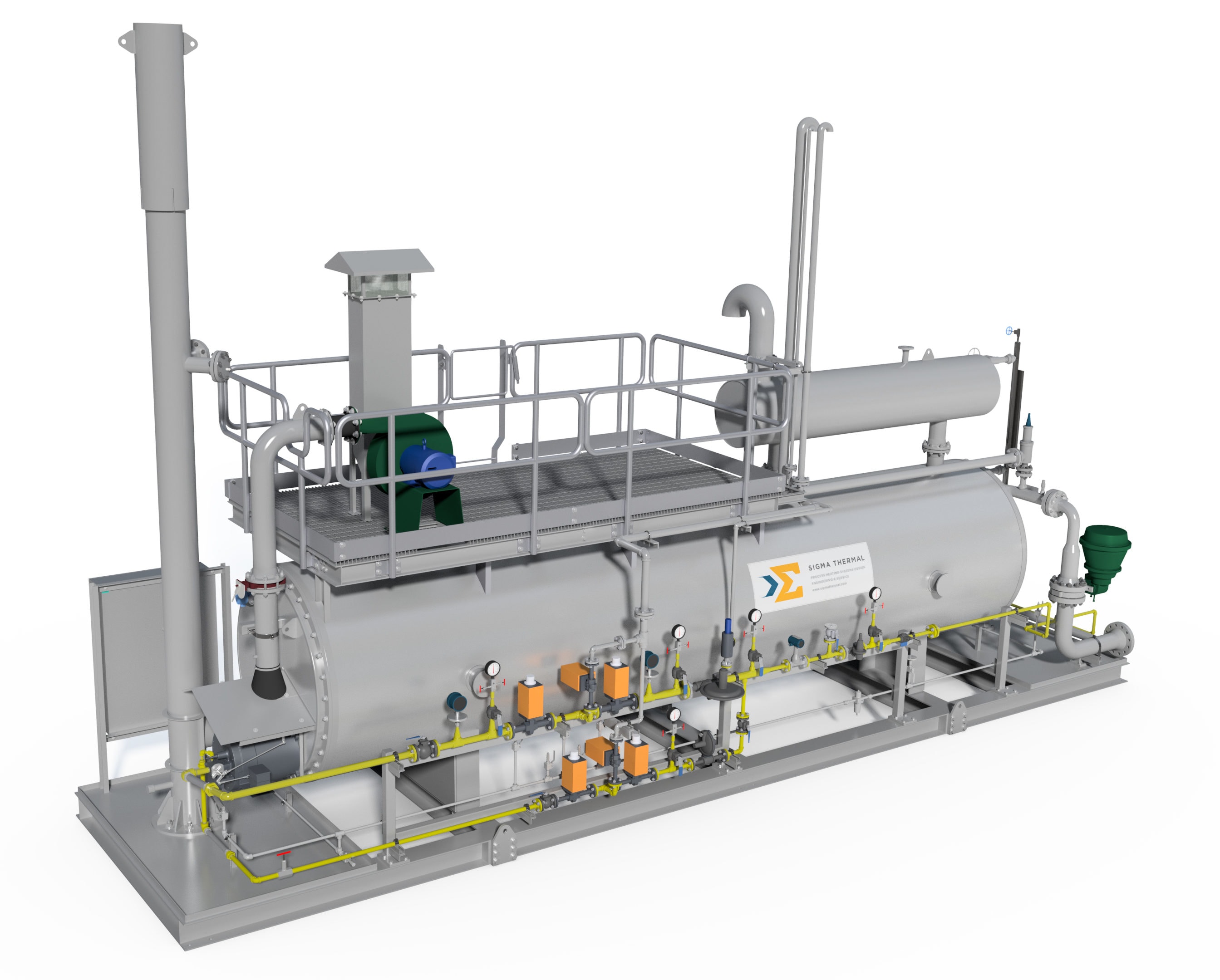

Two categories of heaters are available for plant utility heating.

If you are interested in a plant utility heating system, keep in mind that heating systems can be divided into two distinct categories: direct and indirect. In the case of direct-fired systems, the medium which is to be heated comes into direct contact with an electric heating element or the products of combustion. While indirect heat systems, such as process bath heaters, utilize a heating medium which is used to distribute heat to the desired locations via the chosen medium. There are a few factors that must be weighed when selecting plant utility heating equipment.

Direct-fired heating systems are cost-effective, able to achieve high process temperatures, and are often ideal for dedicated applications. For applications in which heat is desired in multiple areas, such as pre-heating of combustion gas and process reboilers, indirect heating is typically the preferred choice. Our team of engineers at Sigma Thermal can assist customers with selecting the ideal heating system for their specific application.

The heat from indirect heating systems may be supplied via steam, oil, or a water/glycol mixture. Steam has the advantage of being a very inexpensive and efficient heat transfer medium capable of achieving high temperatures at superheated conditions. Oil mixtures are capable of operating at temperatures up to 750°F and water/glycol up to 350°F (under blanket), both eliminate the need for costly high-pressure rated systems. Once again, the optimal choice is dependent on a number of factors and can be evaluated based on the specific application.