Thermal Fluid Heating Systems

Leave a CommentProcess Bath Heaters

Leave a CommentA process bath heater allows a user to indirectly heat process liquids and gases by submerging a process coil into a heated bath solution.

A process bath heater is a simple and safe method for indirectly heating various process mediums. A bath solution is heated by a fire tube style burner submerged at the bottom of the heater vessel. The bath solution then heats a submerged process coil, in which the flowing process medium is heated. Water-glycol mixtures are very common solutions for most low-temperature heating applications, and can typically be used up to 250F. Salt melts can be used to meet the higher operating temperature requirements in some specialized applications.

Amine & Glycol Reboilers

Leave a CommentIn natural gas and crude oil refining, corrosive hydrogen sulfide (H2S) and carbon dioxide (CO2) gasses must be removed from the hydrocarbon stream before the respective fuels can be stored or introduced into the pipeline. To do this, amine and glycol reboilers are used.

At Sigma Thermal, we offer a range of amine and glycol reboiler products, including process bath heaters, electric process heaters, and thermal fluid heating systems. Depending on your needs, we can help customers determine the ideal heater type and size for their amine or glycol reboiler system.

What are Amine and Glycol Reboilers Used For?

Often referred to as acid gasses, hydrogen sulfide and carbon dioxide gasses are present in varying quantities, depending on the well site and formation from which the gas stream originates. The maximum allowance of these compounds in the gas stream is guided by government regulations. To remove acid gas from the crude oil or natural gas stream, the stream is typically treated with an amine compound which absorbs the H2S and CO2. In the amine gas treating process, a reboiler is used to remove the acid gas and recycle the rich amine mixture into a clean stream that is again ready for processing.

Similarly, natural gas streams are treated with glycol to remove water from the natural gas prior to distribution.

How Do Amine and Glycol Reboilers Work in Natural Gas Purification?

Although amine and glycol reboilers both work to purify process streams, they do so using differing processes.

The Role of Amine Reboilers in Natural Gas Purification

Amine reboilers use the following steps to purify a natural gas stream:

- Step one. The natural gas is introduced to the system in the bottom of a tall vertical vessel known as the absorber. The amine is then introduced into the top of the vessel. The amine and gas come into contact with each other via trays or packing.

- Step two. The amine aborbs the H2S and CO2, and the purified natural gas exits from the top of the absorber. This is what’s known as an exothermic reaction. An adequately designed system will regulate the temperature to prevent the amine from absorbing the contaminants.

- Step three. Aftwerward, the amine is sent to the regeneration system, where it is filtered to eliminate any particles and heavy hydrocarbons entrained in the amine.

- Step four. Amine regeneration occurs in two pieces of equipment: the still and reboiler. The still is a vertical vessel containing trays or packing. The amine enters the top of the still, where it encounters the steam generated in the reboiler.

- Step five. Inside the still, the steam provides adequate heat needed to reverse the reaction and dilutes the H2S and CO2 released during regeneration. The increased temperatures and dilution shift the amine regeneration’s equilibrium point to higher amine purities.

- Step six. Lastly, the amine enters the reboiler, which is a shell-and-tube exchanger. Within the exchanger, steam or thermal fluid is used to generate the heat needed to vaporize a portion of water in the amine solution.

The Role of Glycol Reboilers in Natural Gas Purification

Glycol reboilers purify natural gas via the following process:

- Step one. At the beginning of this process, water-free glycol with a purity of over 99% is introduced at the top of the absorber, where it comes into contact with the wet natural gas stream. Through physical absorption, the glycol effectively removes water from the natural gas before it exits from the bottom of the column. Upon leaving the absorber, the glycol stream is typically referred to as “rich glycol.” The dry natural gas leaves the top of the absorption column and is introduced either to a gas plant or pipeline system.

- Step two. Once it has left the absorber, the rich glycol is directed into a flash vessel, where it undergoes a process to eliminate hydrocarbon vapors and separate any liquid hydrocarbons from the glycol. This step is crucial since the absorber typically operates under high pressure, which must be reduced prior to the regeneration step. Because of the rich glycol’s composition, a vapor with a high hydrocarbon content will form when the pressure is reduced.

- Step three. Once it exits the flash vessel, the rich glycol is heated in a cross-exchanger before being introduced to the stripper, or regenerator. They glycol regenerator consists of a reboiler, an overhead condenser, and a column.

- Step four. In the regenerator, the glycol undergoes thermal regeneration to remove any excess water and regain its high purity.

Why are Heating Systems Important for Amine & Glycol Reboilers?

In both of these processes, the respective fluid stream must be heated to a sufficient temperature to strip the acid gas or water without overheating the stream. Overheating of glycol or amines can cause significant degradation to the mixture and reduce the mixture’s ability to absorb the acid gas or water.

Direct fired systems, such as Weir bath heaters, can be used to heat the gas stream. Instead of the coil found in many bath heaters, a Weir bath heater contains a fire-tube with a weir at the end. This type of heater is used throughout the natural gas and crude oil processing industries due to its low maintenance and simplicity. The primary concern with a heater of this type is the direct contact between a very hot firetube and the circulated amine or glycol. Over time this exposure will cause thermal degredation of those chemicals, which require replacement once degraded.

Using indirect heating, like a thermal fluid heating system is an ideal way to provide the constant heat needed to maintain the efficiency of the reboiler, while preventing overheating and degradation. Unlike direct fired heaters, such as the weir bath described above, the temperature that the amine or glycol sees is limited to the temperature of the thermal fluid system. This significantly decreases degredation concerns, and prolongs the life of the expsensive amine or glycol used in the system

Sigma Thermal can assist customers in selecting the ideal heater type and size for the amine or glycol reboiler system.

Learn More About Heating Systems for Amine & Glycol Reboilers

Amine and glycol reboilers are essential components in various industrial processes, particularly in the oil and gas, petrochemical, and chemical manufacturing industries. As an industry leader, Sigma Thermal provides process heating solutions tailored to suit the requirements of various applications. Contact us today or request a quote to learn more about our heating systems for amine and glycol reboilers.

Industrial Waste Heat Recovery Systems

Leave a CommentWhat Is the Inflation Reduction Act?

The Inflation Reduction Act offers individuals a tax credit of up to 40% of the cost of waste heat recovery projects. This initiative targets a new market and customer base without an established vendor supply chain. Additionally, the act includes a provision for retrofitting existing products that have already been sold and implementing waste heat into power generation on a larger scale.

The Inflation Reduction Act offers individuals a tax credit of up to 40% of the cost of waste heat recovery projects. This initiative targets a new market and customer base without an established vendor supply chain. Additionally, the act includes a provision for retrofitting existing products that have already been sold and implementing waste heat into power generation on a larger scale.

Thermal Fluid Systems

Leave a CommentSigma Thermal offers various types of thermal fluid heaters as well as complete thermal fluid systems.

A thermal fluid system is more than just a heater, and all the components of the system must work together in harmony for proper performance.

Purchasing a complete thermal fluid system from Sigma Thermal will ensure that your system operation functions reliably.Thermal fluid heating is a type of indirect heating in which a liquid phase heat transfer medium is heated and circulated to one or more heat energy users within a closed loop system. Thermal oil, glycol, and water are common heat transfer mediums for these systems.

Standard and custom heaters are available in gas-fired, oil-fired, electric and biomass-fired configurations. While the basic components of a complete thermal fluid system are the same, the heater designs vary considerably based on the fuel source. For detailed information on specific heater designs please select from one of the heater options below.

If you would like to speak with a thermal fluid systems expert or if you already understand your needs, contact us or, submit an RFQ to our application engineers today.

Pre-Engineered HC2 Gas Fired Heaters

Comments Off on Pre-Engineered HC2 Gas Fired Heaters

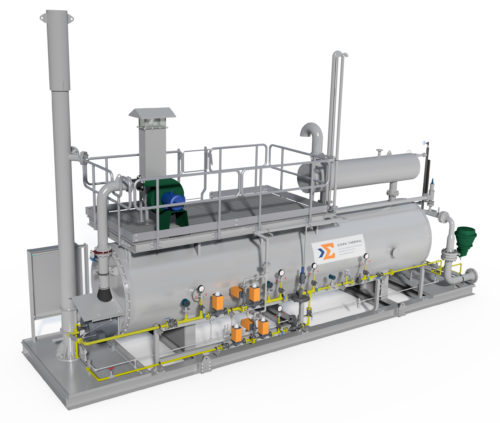

Thermal Fluid Heating Systems

The pre-engineered HC2 thermal fluid heater is available in standard sizes from 500,000 to 100 MM BTU/hr. Configuration options include vertical up-fired, vertical down-fired, and horizontal. This system is skid mounted with a burner and integrated control panels.

To view all heater models, technical specifications, and standard dimensions download our pre-engineered HC2 brochure.

Sigma Thermal also offers custom thermal fluid heater designs for a wide variety of project-specific design challenges.

Pre-Engineered Design Features

- Dual helical coil design with 3 flue gas passes along the coil

- Liquid or vapor phase service up to 675°F

- Flue gasses are significantly cooled, eliminating the need for most internal shell insulation

- Vertical and horizontal configurations

- The heater shell is externally insulated with mineral wool insulation and covered with aluminum cladding

- High turndown gas or oil-fired burners for use with traditional or alternative fuel sources

- Advanced control systems with standard configurations for simple and cost-effective control and for PLC-based control with HMI

- Available option for economizers to increase thermal efficiency to 93% or higher LHV Basis

- Option for ultra-low emissions burners meet the most stringent requirements

- Option for alternative area classifications and code compliance such as CSA, ATEX/CE, etc

If you already understand your needs, you can submit an RFQ here. If you have questions, contact an application engineer today.

Waste to Power

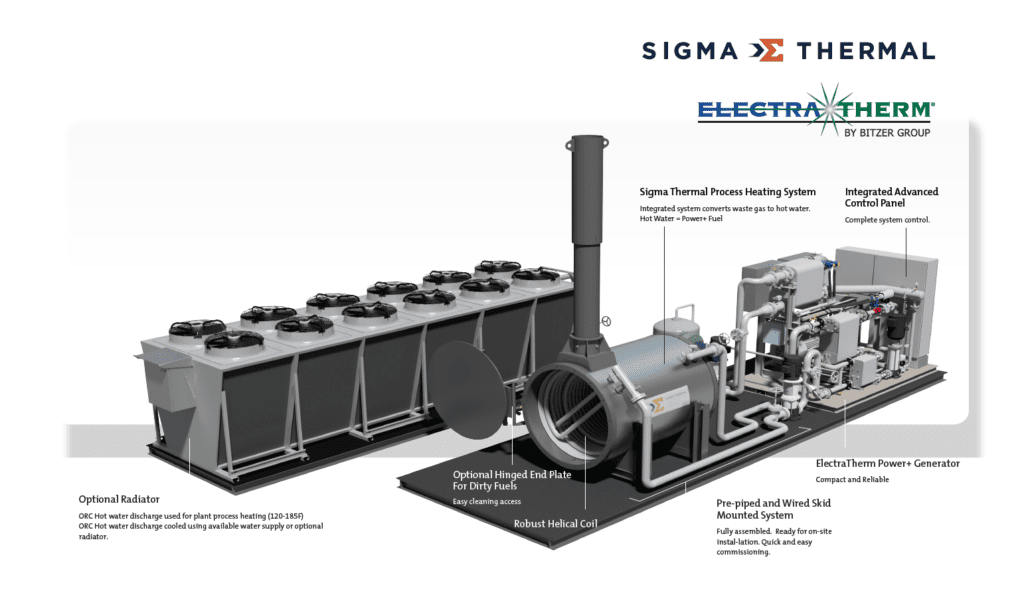

Comments Off on Waste to PowerNextGen Emissions Reduction System + Power

To convert heat to energy into usable electricity, Sigma Thermal can offer and integrated package containing an Organic Rankine Cycle (ORC) generator, helical coil heater, condenser, and evaporator. The waste fuel is captured by an industrial process and used for power conservation. We call it the NextGen Emissions Reduction System + Power, and when it is utilized, gas and oil production, wastewater treatment plants, landfills, farms, and other waste fuel-producing facilities can greatly reduce emissions while minimizing or eliminating flaring.

This total waste to power packaged solution converts waste gas to heat energy for the on-site generation of power that can be used to offset expensive on-site energy costs or provide a backup energy source. The system only requires gas and electrical interface to the skid edge, with multiple burner options available to meet strict emissions requirements.

Dewpoint Heating

Comments Off on Dewpoint HeatingNatural Gas Dew Point Heaters

The temperature at which air becomes saturated with moisture is referred to as dew point. This means that in a saturated state the air is holding the maximum amount of moisture possible at its current temperature. Dewpoint heating increases the established temperature above the dew point to remove excess moisture content.

Dewpoint heating is a crucial component of fuel gas heating for gas turbines and power generation. Fuel gas often contains moisture and contaminants; therefore, dewpoint heating must be utilized as part of the fuel gas conditioning system to deliver clean gas (fuel) to turbines. Typical fuel gas conditioning systems include a fuel gas heater (also known as a dew point heater, or natural gas heater), pressure regulators, and coalescing filters.

Gas Turbines

Dewpoint heating ensures that water or fuel gas condensates do not enter the gas turbine, as they can damage the equipment. Moreover, dewpoint heating guarantees the gas is heated to the most efficient temperature before entering the turbine. During natural gas processing, fuel gases are pushed through a sophisticated network of pipelines from the location at which they originate to other locations where they are needed (i.e. turbines).

The gas must be highly pressurized to move efficiently through the pipelines. This means that the high pressure of incoming fuel must be reduced before it can be used at its destination. When the pressure of the gas is reduced, its corresponding temperature is also reduced; this is known as isenthalpic expansion or the Joule-Thomson effect. Depending on how much the pressure is reduced, water can condense, or in the case of a hydrocarbon, hydrate formation can occur. This occurrence can cause damage to equipment or devices downstream of the pressure reduction. One way to mitigate this is to heat the gas before the pressure is reduced. Therefore when the pressure is reduced, the temperature of the gas stays above the dewpoint or hydrate formation threshold.

Power Generation Demand

With rising power demands, anticipate that EPCs and OEMs will take longer to complete their project cycles. This makes it vital to coordinate the procurement of fuel gas heaters well in advance to avoid delays. Also, take note of some of the dewpoint heating challenges that arise when power demands increase:

• Lower efficiency fuel gas heater due to poor shell side heat transfer.

• Large fuel gas heaters that are existing, become even larger as power demand increases.

• Flow rates might vary, based on the number of turbines or auxiliary systems firing off the fuel gas.

Jacketed Vessels

Comments Off on Jacketed VesselsFluid management can be a sensitive business; whether dealing with chemical, food and beverage, or simply water for industrial processing, efficient and accurate liquid maintenance is crucial to an operation’s success.

At Sigma Thermal, we craft custom thermal fluid heating systems to outfit tanks, vessels, heated molds, building heaters, autoclaves, reactors, and much more. Using thermal oil, glycol, and water as heat transfer mediums, these systems can be combined with a jacketed vessel for exceptional fluid management solutions.

What Are Jacketed Vessels?

Jacketed vessels and pressure vessels can be crafted in a wide assortment of styles to meet an operation’s particular processing needs. Put simply, a standard jacketed vessel introduces a secondary enclosure over a structural shell. The jacket creates a cavity to be utilized for heating and cooling management, usually by filling the space with a circulating fluid.

These systems create excellent heat transfer: they’re efficient, easy to control, and maintain excellent product quality. By introducing agitation in the jacketed vessels, it’s also possible to improve the homogeneity of the fluid properties, allowing for more consistent temperature or concentration levels.

Types of Jacketed Vessels

There are three main styles of vessel jackets available:

- Conventional vessel jackets offer a complete extra covering for all or part of the vessel. These are ideal for high-pressure applications and offer unique insulation benefits, creating both an inner and outer vessel wall. These jackets come in baffled and unbaffled styles, with agitating nozzles helping to improve turbulence and overall efficiency in the absence of baffles.

- Dimple vessel jackets utilize a light-gauge metal jacket affixed to the original vessel via spot or plug welds. This type of system offers strength and durability with minimal additional weight or expense, plus the advantage of natural turbulence as media flows past the dimple points.

- Half-pipe coil vessel jackets are preferred for high-temperature industrial processing applications. These jackets are also excellent for heat transfer and thermal fluid heating systems, particularly when the utility fluid is a liquid. These jackets can be divided into multi-pass zones for maximum flexibility.

Heat transfer efficiency can vary dramatically from one design to another and from one processing application to another. Generally speaking, a conventional jacket will demand greater shell thicknesses and engineered expansion joints to compensate for the stresses of thermal expansion, especially if the jacket and shell have been manufactured from different materials. For a thermal fluid heating system, dimpled jackets and half-pipe coil vessel jackets are typically the most efficient options.

Industries and Applications

The closed-loop heating system of a jacketed vessel allows for great convenience in batching processes. Many industries require that a vessel be both heated and cooled as part of a single process; a well-designed jacket with a thermal fluid system is a seamless way to achieve the necessary temperatures.

Glass-clad vessels and setups that require frequent cleaning also benefit from jacketed systems, as it’s difficult to equip such vessels with internal coils for heating or cooling. Below are just a few of the many industries benefitting from the convenience and reliability of thermal fluid heating in jacketed vessels.

- Chemicals and chemical processing

- Pharmaceuticals

- Food and beverage

- Milk and dairy

- Brewing and distilling

- Asphalt and roofing

Thermal Fluid Systems for Jacketed Vessels From Sigma Thermal

The team at Sigma Thermal is proud to offer a full range of thermal fluid heating systems for jacketed vessels and jacketed reactor heating and cooling applications. Our engineers can develop custom designs to fit any set of operating parameters, working closely with clients throughout every step of the process.

To learn more about our thermal fluid systems, or to discuss how Sigma Thermal can help with your next project, request a quote today.

Molten Salts

Comments Off on Molten SaltsMolten salts, sometimes referred to as salt melts, are a family of products used for a wide range of applications like high-temperature process heating, heat treating and annealing of steel, and thermal storage in solar thermal power plants. These salts are composed of fluoride, chloride, and nitrate salts.

Molten salts have the advantage of very high liquid phase operating temperatures (1,000°F or higher) with little or no vapor pressure. Molten salts can replace organic or synthetic oils in heat transfer applications. While molten salts do offer a substantial benefit with their high operating temperatures, they can also have the undesirable characteristic of very high freezing points (ranging from 248°F to 428°F).

Molten salts have the advantage of very high liquid phase operating temperatures (1,000°F or higher) with little or no vapor pressure. Molten salts can replace organic or synthetic oils in heat transfer applications. While molten salts do offer a substantial benefit with their high operating temperatures, they can also have the undesirable characteristic of very high freezing points (ranging from 248°F to 428°F).

There are three primary types of molten salt heating systems: salt bath heaters, circulated molten salt, and direct heating for applications like heat treating metal assemblies. There can challenges with all of these system types: metallurgy, instruments, system component selection, heat tracing, melting and draining, just to name a few.

Circulated Molten Salt Systems

Circulated molten salt systems are used to distribute hot liquid salt as a heat medium to heat exchangers or other process heat consumers.

Function & Design

Once the energy is needed, the molten salt circulation process begins. Most systems maintain the salt above its freezing point to avoid the process of remelting, but during commissioning or a cold restart situation the salt is melted in a hot salt tank. The molten salt is then circulated through a closed loop system using a circulation pump specifically designed for pumping hot salt. Fluid circulates from the hot salt tank to a fired heater or electric heater, out to the user, and then back again to the hot salt tank.

The system is generally designed in such a way that hot salt will return to the hot salt tank if and when the circulation pumps are turned off. It is unique from other closed loop heating systems because of the freezing point of the salt. The system has to be designed using a hot salt tank, to which the fluid always returns when the system is down.

These systems should be heated and designed to prevent freezing or thermal shock in the circulation piping. Molten salt is stored in these systems at temperatures of 1050°F at normal atmospheric pressure. In these systems, sensors are applied to measure and monitor liquid levels, pressures, temperatures, and flow rates.

Circulated molten salt systems can provide plants with an integrated energy storage option designed to meet specific application needs. This energy storage concept is commonly used in solar power plants to store heat energy for power production at night time or overcast periods.

Hot Salt Tanks

The hot salt tank is a critical part of a circulated molten salt system, helping to move molten salt through the generator, and then providing electric power to the application.

Molten salt systems typically function with two storage tanks at different fill levels and temperatures, hot and cold salt tanks. The molten salt in the cold storage tank moves back through the cycle, while the salt contained in the hot salt tank moves on to generate energy for the system.

The system circulation pumps are typically installed in this tank, along with either electric elements or a fire tube that is used as a heat source for melting solid salt. These tanks are also frequently heat traced and can be insulated with ceramic material and a protective liner. By insulating the tank, you insure the best possible performance.

Salt Bath Heaters

Salt bath heater systems rely on natural convection processes without the use of circulation pumps. These systems are designed to perform at high temperatures to provide energy for a variety of applications.

Function & Design

Salt bath heaters work by heating a vessel of salt with a fire tube style burner or electric elements submerged at the bottom of the vessel. The hot salt then heats a submerged process coil, in which the flowing process medium is then heated. Heat energy is transferred from that tube to the bath fluid. The heat transfer salts operate in temperatures up to 800°F.

Design considerations must be made for loading and melting of solidified salt. A poor design could result in damage to the heater vessel or fire tube during start-up from a cold condition.

Salt bath heaters are commonly used for regeneration gas heating in molecular sieve applications, although they are suitable for other applications requiring a simple indirect heating system design with elevated operating temperature capabilities.

At Sigma Thermal, we design and manufacture circulated molten salt systems, hot salt tanks, salt bath heaters and electric heaters. We can custom design a fully automated system for your process needs, contact us today to learn more about our capabilities.