Automation Solutions

Leave a CommentSigma Thermal Automation offers comprehensive and cost effective solutions to complex industrial challenges.

Our experienced engineers, designers, programmers and fabricators work together to execute all project specifications and requirements.

Electric Process Heaters

Leave a CommentSigma Thermal offers standard and custom-engineered electric immersion and electric circulation heaters and controls.

Electric process heaters are used in many industrial process applications to heat liquids and gases. Sigma Thermal Immersion and Circulation electric heaters typically range from 2 to 60 watts per square inch. These heaters are designed and engineered for versatility and are capable of meeting most applications and site requirements.

Sigma Thermal’s electric process heaters are manufactured to the highest quality standards and they are designed to meet ASME Section VIII Div I, CRN and PED. Whether shipped loose or packaged as a skid, Sigma Thermal can provide a complete solution for your application.

For more information submit an RFQ or contact an application engineer directly.

Industrial Waste Heat Recovery Systems

Leave a CommentBiomass Energy Systems

Leave a CommentProviding modern Biomass-fired energy systems and related equipment for industrial clients worldwide.

Sigma Thermal provides complete packaged biomass systems for industry. The design, engineering, and manufacturing of our systems are backed by decades of energy experience. Packaged biomass energy systems incorporate a fuel feed system, ash handling system, and electric automation controls. Installation supervision, training, parts, and equipment service management are provided to help maintain and support efficient operation for the life of the system.

Reciprocating Grate Furnace Design

The Sigma Thermal reciprocating grate furnace is the most effective design for complete combustion of waste materials with low heating value, high moisture content, and high ash content. Our design allows for finite combustion control, minimizing emissions and utilizing a large range of different waste fuels, with varying characteristics (i.e. chemical composition, fuel size, and moisture content).

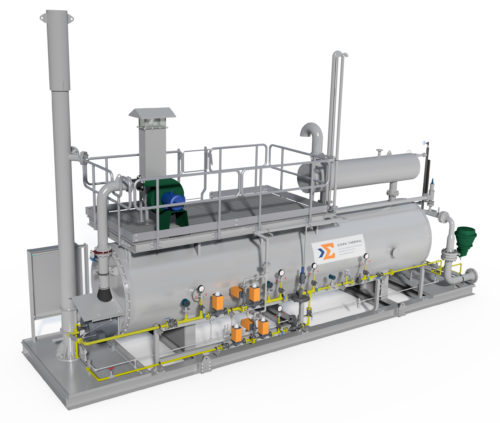

Process Bath Heaters

Leave a CommentA process bath heater allows a user to indirectly heat process liquids and gases by submerging a process coil into a heated bath solution.

A process bath heater is a simple and safe method for indirectly heating various process mediums. A bath solution is heated by a fire tube style burner submerged at the bottom of the heater vessel. The bath solution then heats a submerged process coil, in which the flowing process medium is heated. Water-glycol mixtures are very common solutions for most low-temperature heating applications, and can typically be used up to 250F. Salt melts can be used to meet the higher operating temperature requirements in some specialized applications.

Direct Fired Heaters

Leave a CommentSigma Thermal offers convection style, API 560, and non-API radiant convective heaters from 1MM to 80MM Btu/hr.

A direct fired heater is a style of heater in which a burner provides hot gasses that transfer their heat energy to a process liquid or gas flowing directly through coils installed inside the heater vessel. Direct fired heaters can utilize radiant and/or convection heat transfer sections, and can be configured in many different ways depending on the customers’ specific requirements. Due to the flexibility in design, virtually any style of furnace burner can be used in single or multi-burner configurations. For help selecting the right solution for your project, contact our application engineers today.

A direct fired heater is a style of heater in which a burner provides hot gasses that transfer their heat energy to a process liquid or gas flowing directly through coils installed inside the heater vessel. Direct fired heaters can utilize radiant and/or convection heat transfer sections, and can be configured in many different ways depending on the customers’ specific requirements. Due to the flexibility in design, virtually any style of furnace burner can be used in single or multi-burner configurations. For help selecting the right solution for your project, contact our application engineers today.

Thermal Fluid Heating Systems

Leave a CommentA thermal fluid system is more than just a heater, and all the components of the system must work together in harmony for proper performance. Purchasing a complete thermal fluid system from Sigma Thermal will ensure that your system operation functions reliably.

Thermal Fluid Heating

Thermal fluid heating is a type of indirect heating in which a liquid phase heat transfer medium is heated and circulated to one or more heat energy users within a closed-loop system. Thermal oil, glycol, and water are common heat transfer mediums for these systems.