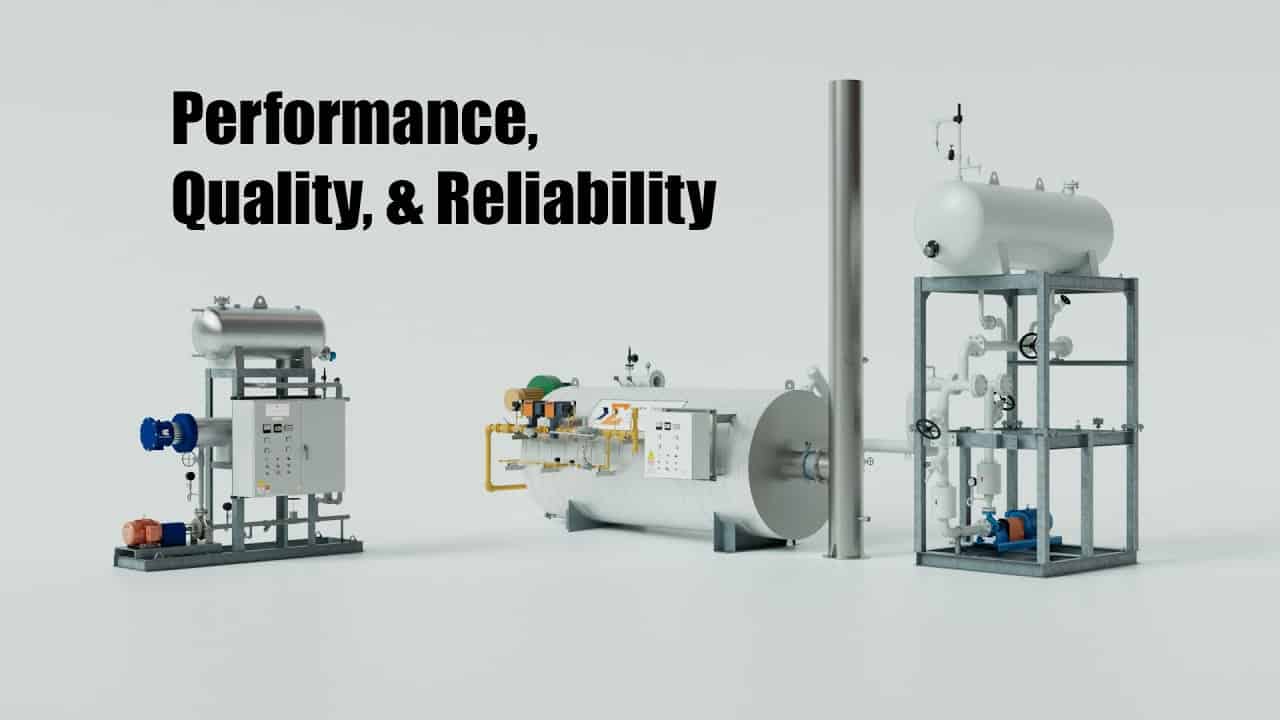

Thermal Fluid Heating Systems

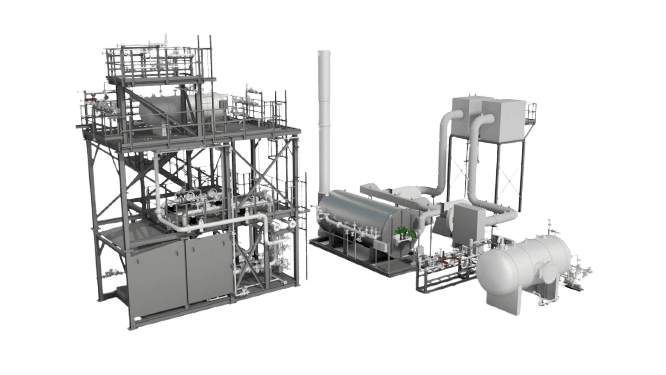

A thermal fluid system is more than just a heater, and all system components must work together in harmony for proper performance. Purchasing a complete system from Sigma Thermal will ensure that your industrial operation is reliable.

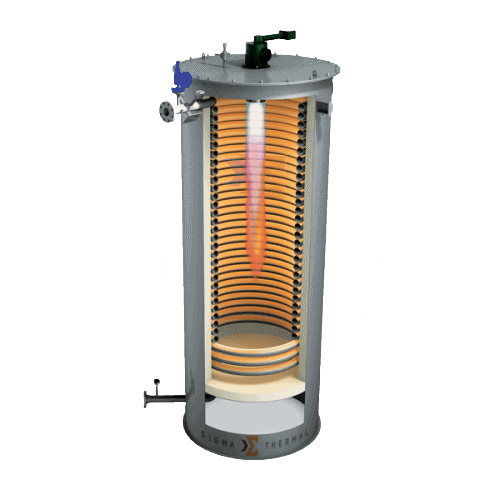

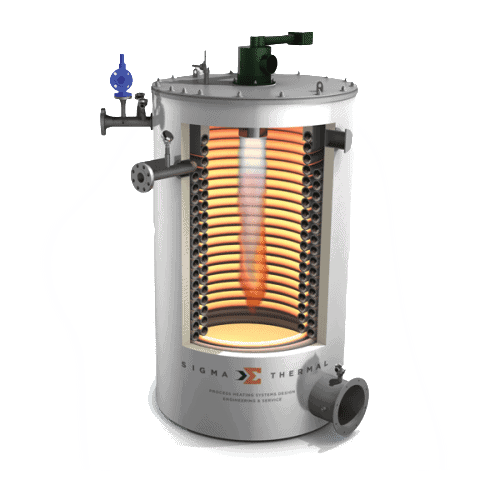

Thermal Fluid Heating

Thermal fluid heating is a type of indirect heating in which a liquid phase heat transfer medium is heated and circulated to one or more heat energy users within a closed-loop system. Thermal oil, glycol, and water are common heat transfer mediums for these systems.

WATCH VIDEO

Thermal Fluid System Components

Packaged components enhance efficiency, ensuring a good return on investment. Overall, Sigma Thermal's expertise enables the creation of solutions that effectively address diverse thermal fluid requirements.

Examples:- Expansion & Drain Tanks

- Temp Control Skid Packages

- Ladders & Access Platforms

- Burner Management Controls

- Tanks & Vessels

- Secondary Loops

- Exhaust Stacks

Typical Applications

- Tank heating

- Platen/Press heating

- Indirect steam generators

- Crude oil heating

- Suction heating

- Ovens and fryers

- In line liquid heating

- Calendar roll heating

- Reactor vessel heating

- Natural gas heating

- In line gas heating

- Building heaters

- Process reboilers

- Jacketed vessel heating

- Heated molds or dies

- Autoclaves

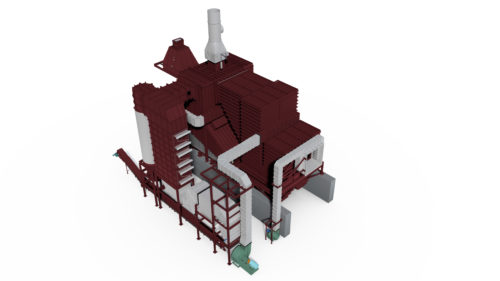

Economizers

With the typical elevated operating temperatures associated with thermal oil systems, it can be difficult to obtain high efficiencies in the heater alone. Sigma Thermal offers a wide variety of economizers to fit your process requirements, increase your thermal efficiencies, and lower your operating costs.

Common Waste Heat Consumers:- Combustion Air Pre-heat

- Steam Ejectors

- ORC Generators

- Wash Water Pre-heat

- Boiler Feedwater

- ORC Generators

- Building Comfort Heat

- General Process Heat

Request a Quote From Sigma Thermal

We integrate superior project execution and engineering expertise with the customer support you need.

Our Blog

Understanding Thermal Fluids & Thermal Fluid Systems

Thermal Fluid Management • Advantages of Thermal Oil Heating Systems Types of Thermal Fluid Heaters • Work With Sigma Thermal The demand for process...

READ MOREAdvantages and Uses of Molten Salt Heating Systems

Molten salts, also called salt melts, are critical in various industrial heating applications. Nitrate salts are most commonly used in industrial heating applications, but...

READ MORE