Biomass Energy Systems

Providing modern Biomass-fired energy systems and related equipment for industrial clients worldwide.

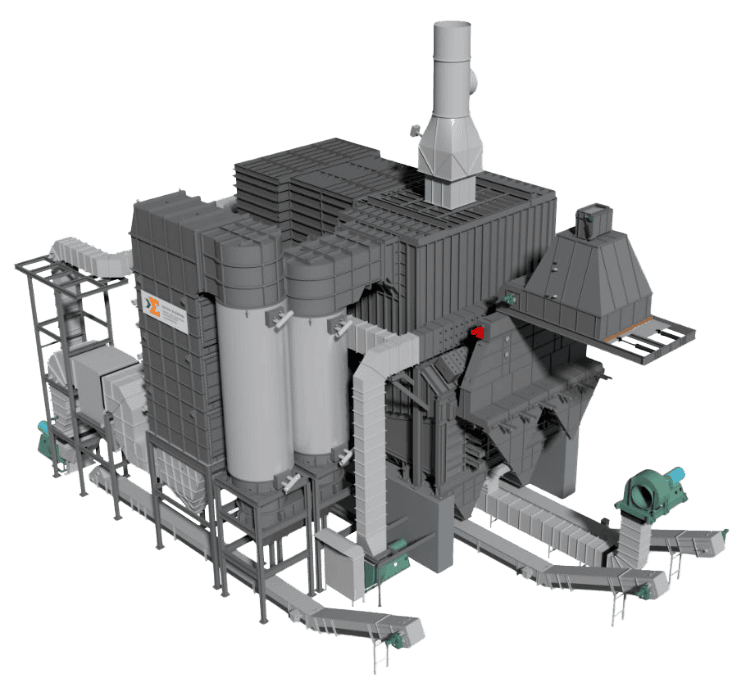

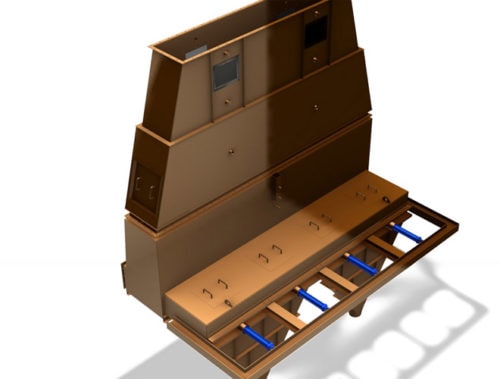

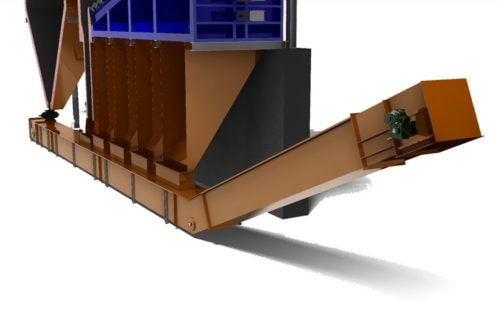

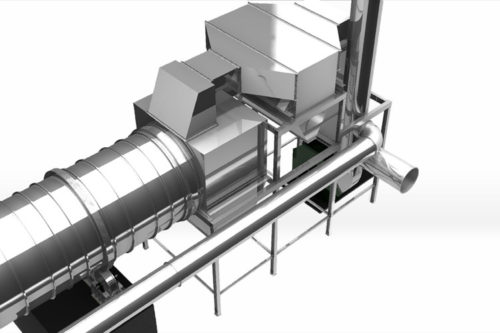

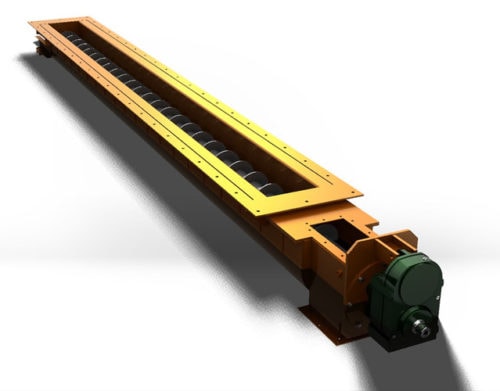

Sigma Thermal provides complete packaged biomass systems for industry. The design, engineering, and manufacturing of our systems are backed by decades of energy experience. Packaged biomass energy systems incorporate a fuel feed system, ash handling system, and electric automation controls. Installation supervision, training, parts, and equipment service management are provided to help maintain and support efficient operation for the life of the system.

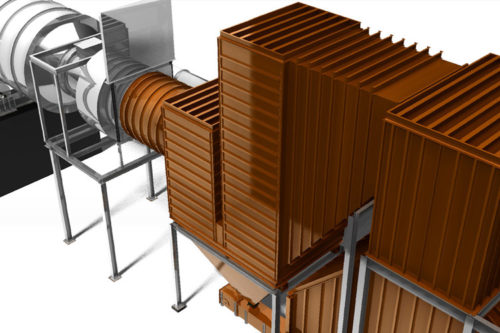

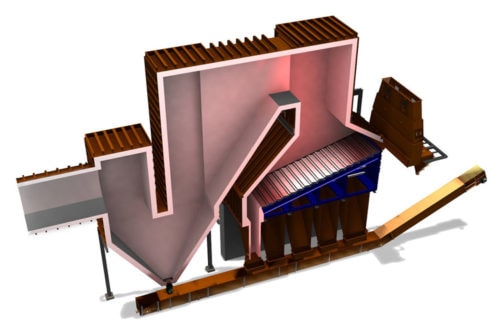

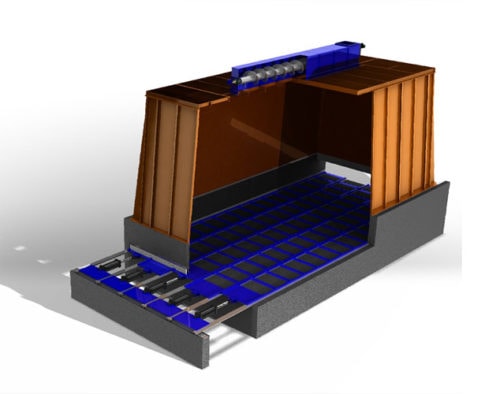

Reciprocating Grate Furnace Design

The Sigma Thermal reciprocating grate furnace is the most effective design for complete combustion of waste materials with low heating value, high moisture content, and high ash content. Our design allows for finite combustion control, minimizing emissions and utilizing a large range of different waste fuels, with varying characteristics (i.e. chemical composition, fuel size, and moisture content).