Benefits of Thermal Fluid Heaters in the Oil and Gas Industries

Industrial thermal fluid systems are indirect heating systems that increase the temperature of process fluids, such as crude oil and petroleum products in the oil and gas industry. These heating

systems offer several key advantages over steam systems. This blog will explore industrial thermal fluid heaters briefly, including the benefits they provide for various applications in the oil and gas industry.

What Are Thermal Fluid Heaters?

An industrial thermal fluid heater is a closed-loop heating system that uses a heat medium like thermal oil, water, or water/glycol to increase the temperature of the process fluid. This indirect heating process relies on oil, natural gas, wood, or electricity to heat the thermal medium. Once the medium reaches the desired temperature, a pump circulates it to one or multiple heat exchangers or consumers.

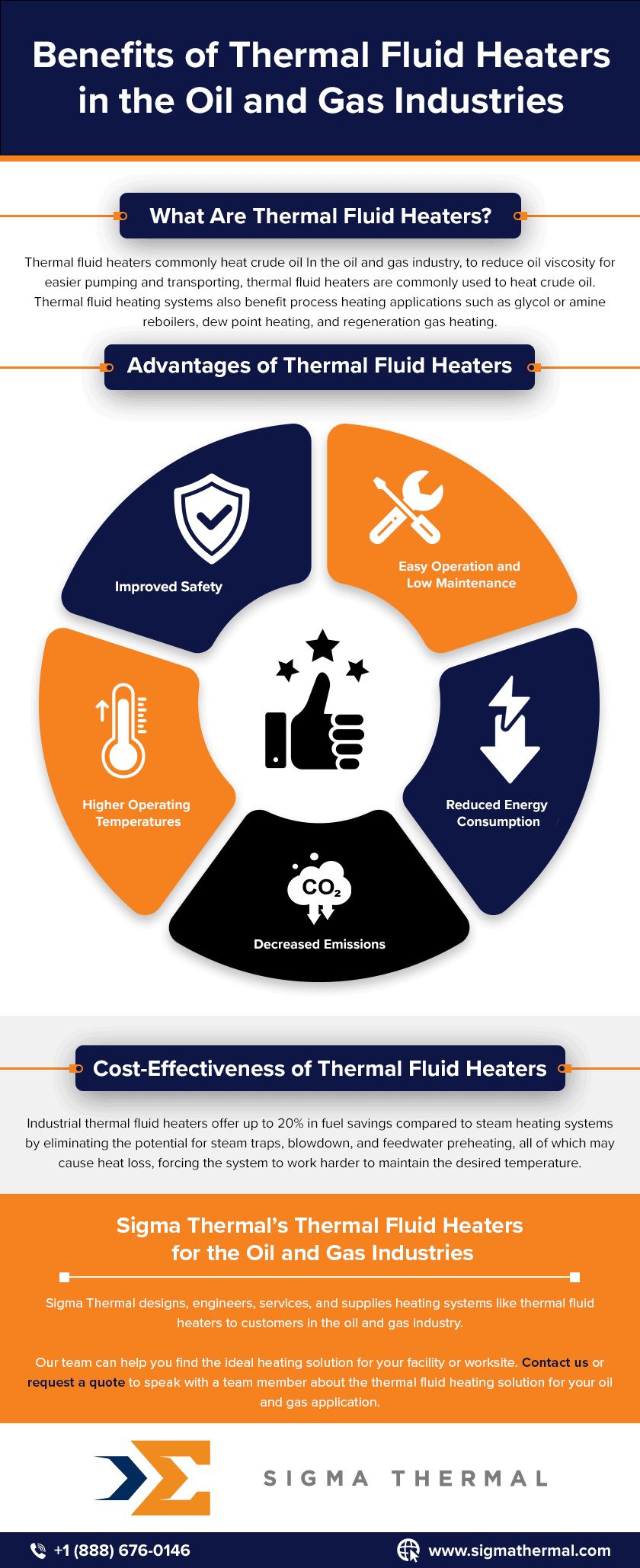

Thermal fluid heaters commonly heat crude oil in the oil and gas industry to reduce oil viscosity for easier pumping and transporting. These heaters also facilitate process heating applications such as dew point heating, regeneration gas heating, and glycol or amine reboilers.

Advantages of Thermal Fluid Heaters

Industrial thermal fluid heaters deliver a variety of benefits that make them an ideal choice for oil and gas heating applications:

- Easy Operation and Low Maintenance: Thermal fluid heaters are low maintenance and easy to operate. Thermal oils can lubricate the thermal fluid heater so that the heater does not require monitoring or chemical treatment to prevent corrosion.

- Reduced Energy Consumption: Thermal fluid heaters offer up to 20% less energy consumption than steam heaters, avoiding heat loss from feedwater preheating, blowdown, and steam traps.

- Decreased Emissions: These heaters also result in reduced total exhaust emissions due to higher thermal effeciency.

- Higher Operating Temperatures: Because thermal oil’s boiling point is higher than that of water, thermal fluid heaters can operate at a higher temperature range (-40 to 750 °F or -40 to 400 °C) than steam heaters can. Thermal fluid heaters can also heat process fluids at a range of different operating temperatures using secondary control loops.

- Better Safety: Since thermal fluid heaters operate at lower pressures than steam boilers, thermal fluid heaters don’t provide a risk of pressure related explosion tofacility personnel.

Cost-Effectiveness of Thermal Fluid Heaters

Thermal fluid heaters are a cost-effective solution for the oil and gas industry. Compared to steam systems, thermal fluid systems offer more long-term cost savings in the form of reduced maintenance and lower overall operating expenses. Plus, thermal fluid heaters certified under ASME Section VIII typically don’t require a licensed boiler on site.

Industrial thermal fluid heaters offer up to 20% in fuel savings compared to steam heating systems by eliminating the potential for steam traps, blowdown, and feedwater preheating, all of which may cause heat loss and force the system to work harder to maintain the desired temperature.

Sigma Thermal’s Thermal Fluid Heaters for the Oil and Gas Industries

Industrial thermal fluid heaters use a combination of water and glycol or thermal oil in a closed-loop system to indirectly heat process fluids. In the oil and gas industry, crude oil needs to be heated to reduce its viscosity and make it easier to transport. Thermal fluid heaters offer several advantages over conventional steam systems, such as higher operating temperatures and lower energy consumption.

Sigma Thermal designs, engineers, services, and supplies heating systems like thermal fluid heaters to customers in the oil and gas industry. Our team can help you find the ideal heating solution for your facility or worksite. Contact us or request a quote to speak with a team member about the thermal fluid heating solution for your oil and gas application.