What Is a Thermal Fluid Heating System?

Heating and precise temperature control are crucial to many industrial processes. These systems also offer consistent performance and work at high temperatures yet low pressures for safer operations. Learn more about thermal fluid heating systems, how they work, their benefits compared to direct-heat and standard steam systems, and other applications.

What Is a Thermal Fluid Heating System?

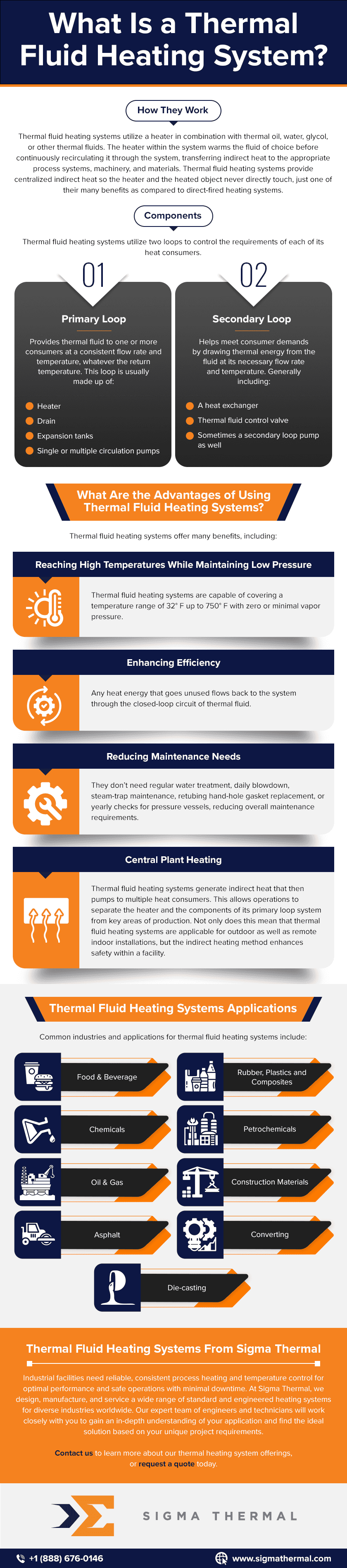

Thermal fluid systems utilize a heater in combination with thermal oil, water, glycol, or other thermal fluids. The heater within the system warms the fluid of choice before continuously recirculating it through the system, transferring indirect heat to the appropriate process systems, machinery, and materials. Thermal fluid heating systems provide centralized indirect heat so the heater and the heated object never directly touch, just one of their many benefits as compared to direct-fired heating systems.

Thermal fluid systems utilize two loops to control the requirements of each of its heat consumers. The primary loop provides thermal fluid to one or more consumers at a consistent flow rate and temperature, whatever the return temperature. This loop is usually made up of a heater, drain and expansion tanks, and a single or multiple circulation pumps.

As for secondary loops, thermal fluid systems can have single or multiple secondary loops. Secondary loops help meet consumer demands by drawing thermal energy from the fluid at its necessary flow rate and temperature. Generally including a heat exchanger and a thermal fluid control valve, these loops sometimes use a secondary loop pump as well.

What Are the Advantages of Using Thermal Fluid Heating Systems?

Thermal fluid heating systems offer many benefits, including:

- Reaching high temperatures while maintaining low pressure. Thermal fluid systems are capable of covering a temperature range of 32° F up to 750° F with zero or minimal vapor pressure, unlike standard steam systems that heat from 250° F to 350° F at a design pressure of 150 PSIG.

- Enhancing efficiency. Unlike steam systems that lose energy through blowdowns and steam straps, thermal fluid systems don’t experience the same auxiliary heating losses. Any heat energy that goes unused flows back to the system through the closed-loop circuit of thermal fluid.

- Reducing maintenance needs. Like steam boilers, thermal fluid heaters necessitate combustion checks. However, they don’t need regular water treatment, daily blowdown, steam-trap maintenance, retubing hand-hole gasket replacement, or yearly checks for pressure vessels, reducing overall maintenance requirements. That said, always follow the maintenance guidelines your manufacturer outlines to achieve maximum functionality.

- Central plant heating. For plants using direct-fired heaters, every operational process requires a heater of its own for adequate heating. Thermal fluid systems, however, generate indirect heat that then pumps to multiple heat consumers. This allows operations to separate the heater and the components of its primary loop system from key areas of production. Not only does this mean that thermal heating systems are applicable for outdoor as well as remote indoor installations, but the indirect heating method enhances safety within a facility.

Thermal Fluid Heating Systems Applications

Common industries and applications for thermal heating systems include:

- Food & Beverage. Fryers for poultry or meat, ovens in bakeries, and snack food production.

- Rubber, Plastics and Composites. Heat for extrusion and molding processes.

- Chemicals. Continuous processing applications and batch reactors.

- Petrochemicals. Catalysis, synthesis, and distillation processes for the petrochemical industry.

- Oil & Gas. Critical for fuel extraction, transport, refining, and recycling.

- Construction Materials. Heat presses and dry kilns in facilities for roofing and engineered wood production.

- Asphalt. Asphalt hot-mix paving and roofing applications for the asphalt industry.

- Converting. Rolling, pressing, printing, and laminating.

- Die-casting. Temperature control in die-casting applications.

Thermal Fluid Heating Systems From Sigma Thermal

Industrial facilities need reliable, consistent process heating and temperature control for optimal performance and safe operations with minimal downtime. At Sigma Thermal, we design, manufacture, and service a wide range of standard and engineered heating systems for diverse industries worldwide. Our expert team of engineers and technicians will work closely with you to gain an in-depth understanding of your application and find the ideal solution based on your unique project requirements.

Contact us to learn more about our thermal heating system offerings, or request a quote today.