Industrial Process Heating Methods

Process heating systems deliver heat to liquid, gas, and solid materials in various industrial settings. Depending on the application, multiple types of heating methods can be used. We will explore several of these industrial heating methods as well as their benefits and applications to help you determine the ideal solution for your application.

The Different Industrial Process Heating Methods

Process heating systems rely on different fuel sources and heating methods to deliver indirect or direct heat to the process material. Here are a few common heating methods.

Combustion or Fuel Based Heaters

Combustion process heaters burn gasses, liquids, or solids to produce and transfer heat to the process material indirectly or directly. Oil, natural gas, coal, charcoal, wood chips, cellulose, and ethanol are common fuel choices. Air or oxygen is introduced to the fuel to achieve combustion. In direct heating, the combustion gas makes direct contact with the process material. In indirect heating, the process material is heated in a vessel away from direct contact with the combustion gas.

Electric Process Heaters

Electric process heaters rely on resistive heating elements through which electric current is passed to generate heat. The heating elements can then be used to directly or indirectly heat processes in tanks, ducts, or circulation vessels.

Heat Recovery and Exchange Systems

Heat recovery and exchange systems rely on a heat exchanger to transfer heat from one process material to another. For example, a manufacturing facility can use a heat exchanger to recover the heat produced by an exothermic chemical reaction and use it to provide heat to another application.

Boilers and Thermal Fluid Heating Systems

Boilers use fuel combustion to produce steam. This process heating method offers simplified transportation, low toxicity, high heat efficiency, and low cost. Boilers are one of the most prevalent process heating solutions in manufacturing facilities. They can be complex and require consideration of various factors to deliver efficiency and performance.

Thermal fluid heating systems utilize a heat transfer medium in the liquid state that is pumped through the heater and out to the heat transfer consumers. These systems commonly use organic or synthetic oils that allow for operation at high temperatures with little or no pressure when compared to boilers.

Hybrid Systems

A hybrid system utilizes multiple energy sources to heat material. For example, a paper manufacturer can use a fuel-based dryer in combination with an electric infrared heater to dry paper.

What Are the Benefits of Industrial Process Heating Systems?

When you partner with an experienced process heating system manufacturer and select the right system, you can enjoy the following benefits:

- Cost Efficiency: A suitable process heating system delivers optimal heat transfer and generation, improving efficiency, reducing energy consumption, and producing a higher quality product at an overall lower operating cost.

- Simple Installation: Quality process heating systems provide an all-in-one solution for heating and control. An experienced heating system manufacturer can deliver a custom solution that meets the specified space requirements and can be quickly assembled and installed on-site.

- Centralized Control: Process heating systems can be managed remotely with advanced instrumentation and controls.

Applications of Industrial Process Heating Systems

Process heating systems are ideal for a variety of flowing liquids, gasses, and air. They are used in the following process heating and industrial applications.

- Caustic Solution Heating

- Fuel Gas Heating

- Hydraulic and Heat Transfer Oils

- Lube Oil and Fuel Oil Heating

- Molten Salts

- Process Air and Gas Heating

- Process Chemical Reactors

- Steam Superheating

- Water Heating

- Water-Glycol Solution Heating

Process Heating Systems From Sigma Thermal

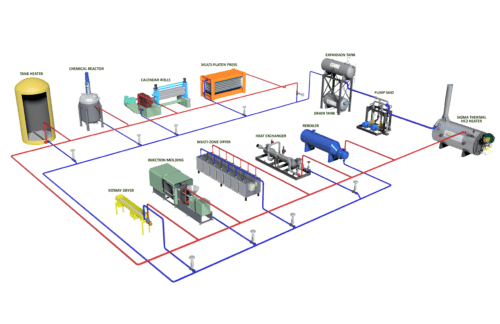

Industrial and manufacturing facilities have a range of choices for process heating methods. There are several types of heating systems available for solid, liquid, and gas materials, with either direct or indirect heating. Working with a knowledgeable and capable partner is vital to selecting the ideal process heating system for your application that delivers optimal performance and efficiency benefits.

Sigma Thermal offers custom and standard process heating solutions for gasses, solids, and liquids. We offer a selection of combustion, electric, heat recovery and exchange, boiler, and hybrid process heaters, all of which can be customized for your specific needs. Sigma Thermal is ISO 9001:2015 certified and serves a worldwide market.

Contact us or request a quote for your application’s ideal process heating solution.