Sigma Thermal’s Glycol Heater Used in Potash Mining

As the potash mining industry continues to grow and change, Sigma Thermal will keep offering innovative solutions with ongoing system design improvements. In this spirit of continuous improvement, we frequently work closely with a global network of industry leaders to develop creative solutions to industry challenges.

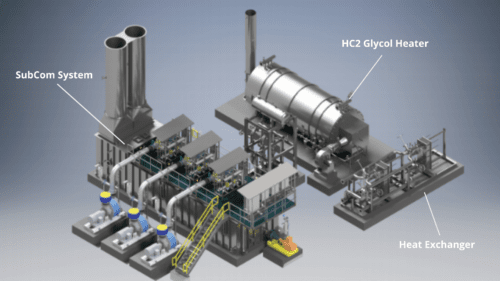

Inproheat Industries, one of our Canadian partners, successfully applied their proprietary brand of Submerged Combustion Technology known as SubCom®, along with a Sigma Thermal heater, to a potash mining project.

The Potash Mining Project – Saskatchewan Canada

A 2019-2020 project in Saskatchewan is a shining example that demonstrates the viability of a new and novel solution for potash solution mining projects. In the early stages of project development, Inproheat Industries was approached to quote a submerged combustion system for heating highly corrosive saturated potash brine to temperatures up to 110° C. Already familiar with the high-energy efficiency characteristics of SubCom and its ability to easily contend with scaling solutions, the engineering team believed that this technology would be ideally suited to the job. Inproheat Industries worked closely with the client to develop the engineering specifications and system designs, which included calling on a select group of trusted industry partners to assist with critical components that would best meet the requirements of the project.

The resulting three-burner SubCom system heats brine to 82° C at 51 MM Btu/h before the brine is driven through a Sigma Thermal HC2 Glycol Heater to further raise brine temperatures to a range of 100° C to 110° C on its way to the injection pumps. The system also includes a Tranter plate and frame heat exchangers to transfer the recovery well brine heat over to the injection brine. The primary objectives of the project were the delivery of a high-efficiency potash mining solution, with a correspondingly low environmental impact, that would provide a significant economic boost to Saskatchewan. Ultimately, Inproheat, Sigma Thermal, Tranter, and other partners assessed the needs of the client and delivered an excellent system solution while providing dedicated support at every stage of the process.

Innovative Solutions From Sigma Thermal

We form strategic partnerships with key industry players to foster results that exceed expectations and set new standards. We work closely with our customers and industry partners to develop innovative solutions to unique and complex challenges. We would welcome the opportunity to learn more about the dynamic goals of your company. Contact the experts at Sigma Thermal to collaborate on heating solutions for your next project.

HC2 Glycol Heater Advantages

SubCom Advantages

SubCom offers multiple advantages when compared to traditional boiler-heat exchanger methods:

- SubCom technology lowers expenditures for fuel, maintenance, and operations.

- The efficiency provided by SubCom drives savings, thus shortening payback periods on capital expenditures.

- Reduced fuel consumption results in proportionally lower greenhouse gas emissions and, where applicable, lower carbon tax costs.