Why Use Thermal Fluid Heating Systems Instead of Water Bath Heaters?

Water bath heaters are a well-established method of heating gas and oil, however, in specific applications, a thermal fluid system can provide more significant benefits and improved performance.

In this blog post, we will explore the unique advantages hot oil heating systems provide, including the following:

- Improved efficiency

- Reduced costs

- More responsive control

In the following sections, we’ll delve deeper into each of these benefits, uncovering how hot oil heating systems can streamline your industrial operations.

Efficiency

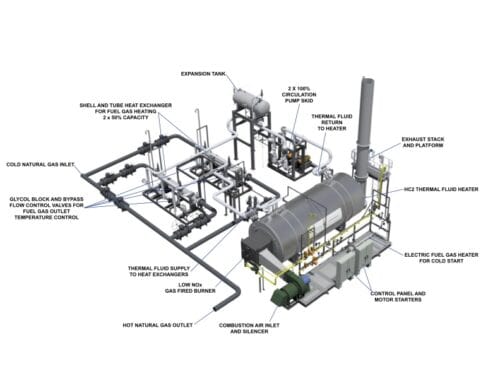

Thermal fluid heating systems are highly efficient. Today’s systems achieve efficiencies ranging from 85% to over 89%. When combustion air preheat is used, they can even reach as high as 93%. In addition, since thermal fluid systems feature a closed-circuit loop of thermal fluid, any unused heat flows back through the system, resulting in minimized heating losses. Higher thermal efficiencies like these result in lower fuel consumption, reduced operating costs, and lower carbon emissions.

Cost

The installed cost of a thermal fluid heating system is typically much lower than a comparable water bath heater. As the demand for heat grows, the cost differential grows also. In smaller-sized systems of up to around 10MM Btu/hr, the installed cost differential is usually between 10% and 20%. In larger systems, installing multiple bath heaters may be necessary to achieve the same performance as a single thermal fluid system, and the cost differential can increase as much as 40% to 50%.

In addition, the cost of thermal fluid is another key consideration. Water bath heaters can have as much as 8 to 10 times more thermal fluid than a comparable thermal fluid system, resulting in hundreds of thousands of dollars of extra initial fluid costs. This fluid must also be maintained and replaced over time, further inflating the lifetime system cost.

The significant difference in fluid fill volume also means that the weight of the water bath heater is many times that of a comparable thermal fluid system. This affects foundation designs and can result in higher construction costs. Due to these factors, a hot oil heater can provide significantly lower operational costs compared to a water bath system.

Control & Turndown

The concept of a water bath heater is relatively simple — it functions as a large, liquid heat sink. The bath is maintained at a constant temperature and the process coil absorbs energy from the bath. However, this concept has several control and responsiveness limitations. For example, due to the large volume of fluid, changing the temperate of the bath liquid takes time.

The speed at which the temperature can rise is limited by the burner’s firing rate. When the burner is turned off, lowering the temperature is dependent on the process coil’s ability to remove temperature from the bath. In either situation, it can take anywhere from 30 minutes to several hours to substantially alter the bath temperature. For this reason, many water bath applications involve a process flow bypass valve to control process temperature while ensuring the bath temperature remains constant.

While this can be an effective control method, it is limited by the ability of the bypass valve. Since bypass valves don’t control well at the bottom end of their control range, if the process flow rate or temperature range varies by more than 10:1, this can pose a potential issue. In contrast to this type of system, a hot oil heater offers dynamic and responsive control. It features excellent turndown capability and quick response times. Since the volume of fluid in these systems is limited, system operating temperatures can be changed quickly. In addition, compared to water bath heaters, process turndown can be exponentially improved by implementing multiple heat exchangers parallel to one another.

Learn More About Thermal Fluid Heating Systems

Hot oil heating systems operate at higher efficiencies than water bath systems and can result in significant savings. Many applications that have traditionally been associated with water bath heaters can actually use a hot oil heater instead, with improved process control and turndown. If you’re considering purchasing a new thermal fluid hot oil heater, it can feel challenging to understand all of your equipment options.

At Sigma Thermal, we can help you learn everything you need to know about hot oil heating systems. Our team designs, engineers, and maintains process heating systems for many industries. We can help you obtain the innovative solutions you need at an affordable price. To get started, request a quote today or check out our eBook for more information.